ISO Cleanliness Codes Explained

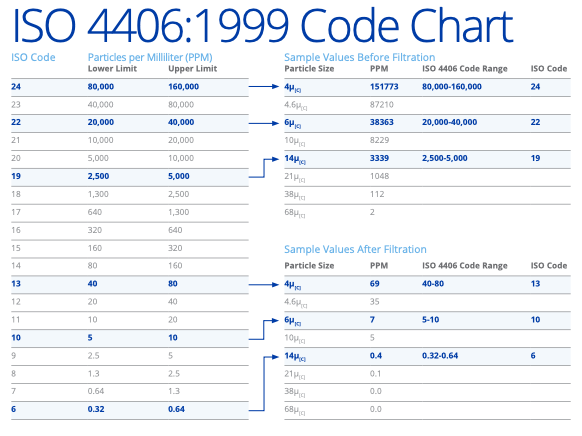

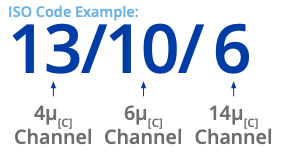

The ISO Cleanliness Code (per ISO4406-1999) is used to quantify particulate contamination levels per milliliter of fluid at 3 sizes - 4µ, 6µ, and 14µ. It is expressed in 3 numbers (example 19/17/14) where each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

ISO Code Limits

Hydraulic component and bearing manufacturers set ISO fluid cleanliness code limits that are the maximum tolerance for fluid contamination under which predictable performance and life can be maintained. These limits often become fluid cleanliness targets at the mill or plant level. Using the upper limit as a target means that you are operating on the absolute edge with no room for error. But there is a better way.

Our mission is to make our customers as efficient as possible. To do this we recommend and help implement operating ISO Codes that are well below OEM upper limits. Our focus is not to hit a valve manufacturer's ISO Code limit but to help our customer reduce servo valve replacements from 220 in one year to 6 in the next by implementing lower operating ISO Codes and drastically reducing component wear/failure. And since that customer could prove that their oil was cleaner than required by spec, those 6 servos in year 2 were replaced under warranty by the manufacturer. Lower operating ISO Codes can extend component life by triple, quadruple, and beyond, resulting in huge reliability, profitability and efficiency gains.

How Clean is my fluid?

Identifying proper sampling ports and locations, taking accurate samples and correctly interpreting results are critical to success. That's why our training and support are based on knowing and understanding the importance of fluid cleanliness and sampling. Hy-Pro is on the front line with on-line particle counters, expertise and strategies to achieve lower operating ISO Codes.

Setting operating ISO Codes.

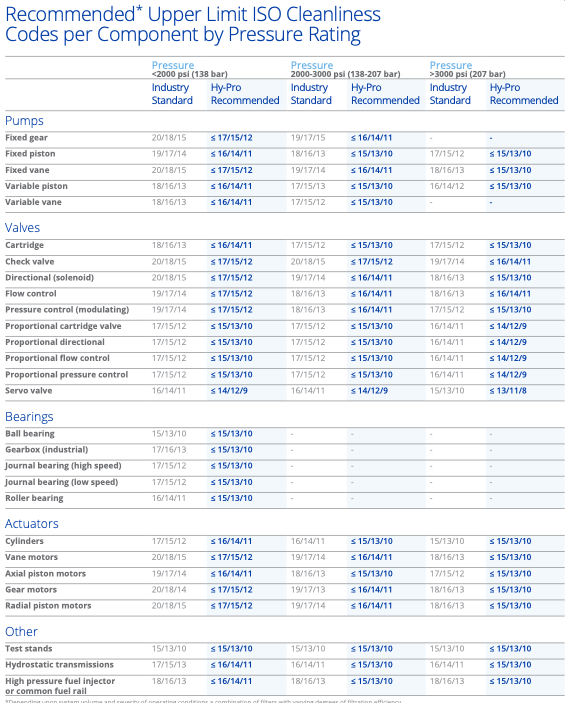

The table below represents Hy-Pro's recommendations for operating ISO Code by component and pressure. These are lower than typical industry standard target ISO Codes and are based on our experience of extending component life and reliability. Other considerations in setting lower operating ISO Codes include:

- Component criticality (turbine hydraulic controls)

- Safety (amusement park hydraulics)

- Excessive shock or vibration (mining excavator)

- High frequency duty cycle (high speed stamping press)

Total System Cleanliness

Upgrading to Hy-Pro DFE rated filter elements, Hy-Dry breathers and adding off-line contamination solutions where needed are a small expense compared to the cost of contamination related component repair and replacement, premature fluid replacement, increased maintenance demands and, worst of all, downtime. By taking these small steps and becoming proactive in preventing contamination, you're setting yourself and your plant up with the best possible chance for success.