The Problem

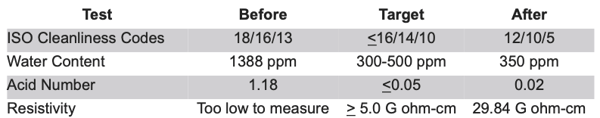

Maintenance professionals explained that though the ISO codes had not exceeded the "high limit" parameters set by the oil manufacturer, they were, however, hovering closer and closer to it, causing the use and purchasing of more filters. Continued research provided maintenance professionals with the information needed to conclude that if the current oil analysis trend was to continue that there could be unexpected downtime in the near future. Because of these three contributing factors, Hy-Pro was contacted and given an opportunity to assess the situation and offer reliable solutions if able.

The Solution

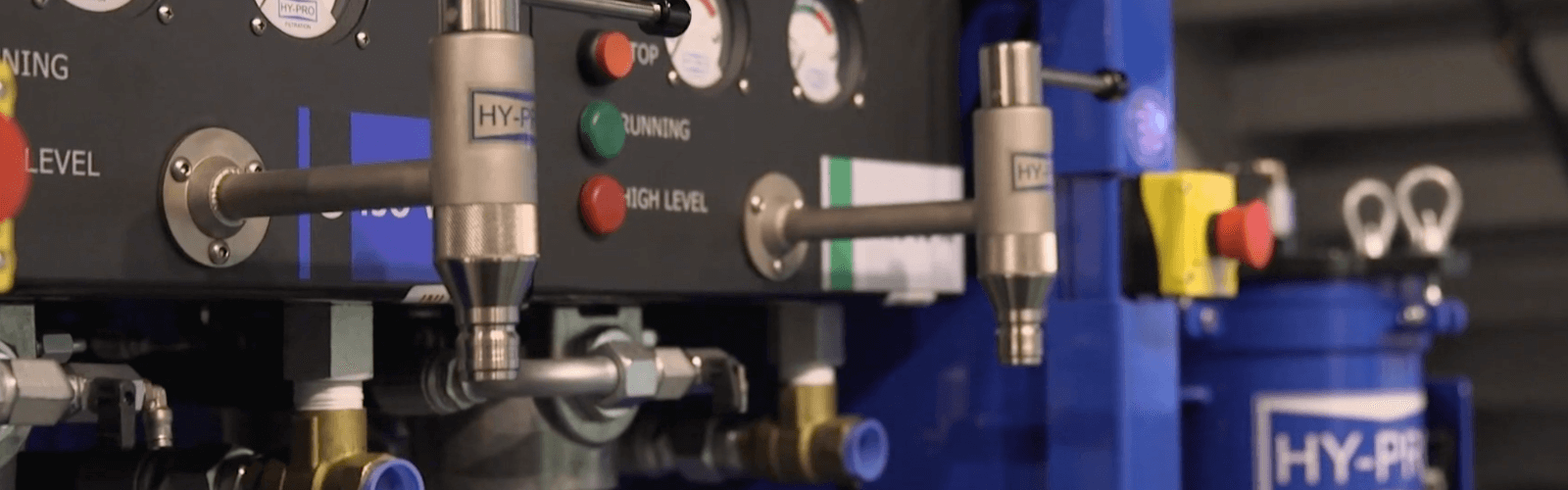

When Hy-Pro's representatives arrived, they initiated their investigation by identifying the lube oil filters they would need to start a system test, ensuring there were proper sample ports for oil testing.

Using particle counting technology, it was found that the paper products manufacturer was achieving ISO codes of 17/14/10. Furthering the exploration, Hy-Pro representatives spoke with on-site maintenance professionals to find ut normal DP ratings, indicated for change, as well as the average element life, which was only 60 days for current filters. After collecting all the evidence, a plan of action was created taking into account goals set by the client. These goals included: reducing the number of filters being purchased each year, lowering labor costs, maintaining or improving current ISO code levels and saving money overall.

The plan of action would include documenting current ISO codes, replacing all current filters in the lube system with Hy-Pro filters, setting a time period of one week to come back and resample the oil, and finally providing replacement elements for when terminal DP was reached and elements needed to be changed. Additionally, they would need to document the length of the Hy-Pro element life and any further changes to the ISO codes.

The Results

After one week's time, Hy-Pros representatives returned to resample the oil. No issues had been reported and as far as the client was concerned, business was as usual. Results from the resampling concluded that, in seven days' time, ISO codes had dropped from 17/14/10 down to 15/13/9. These numbers hadn't been seen in quite some time.

Instructions were left for the client to notify Hy-Pro when they had reached terminal DP for the filter and had to change it out; spare Hy-Pro elements had been left for when this event would occur. Over the next fewmonths Hy-Pro heard nothing from the client. Hy-Pro checked in with them at month one and they nothing to report. After month two they still had nothing to report. Finally, after three months there was still nothing to report, so Hy-Pro set an appointment to come back to the facility on the fourth month to ensure all was right.

However, before arriving, the phone call finally came. At the 120-day mark, terminal DP was reached and the Hy-Pro filters were replaced. Hy-Pro tested the system again, ending with the same ISO code results, 15/13/9, and the client couldn’t have been happier.

What HY-PRO provided:

- DFE Rated Filter Elements