In industrial operations, the efficiency and reliability of your industrial hydraulic systems are paramount. These systems are the muscle behind much of your heavy machinery, and even minor contamination or neglect can lead to costly downtime and premature equipment failure. That's where Donaldson’s professional, specialized service becomes invaluable.

4 min read

Essential Hydraulics Services from Donaldson

By Donaldson Hy-Pro Marketing on Thu, Dec. 11, 2025

Topics: contamination new oil fluid samples samples cleanoil oil handling best practices hydraulic oil cleanliness

9 min read

Understanding ISO 4406 Cleanliness Codes: A Complete Guide to Fluid Contamination and Reliability

By Donaldson Hy-Pro Marketing on Wed, Dec. 03, 2025

Topics: contamination fluid cleanliness ISO Fluid Cleanliness Codes filter elements cleanoil hydraulic oil cleanliness hydraulic oil maintenance lubrication systems

2 min read

24-Hour Turnaround: How Clean Oil Restored Production at a U.S. Paper Mill

By Donaldson Hy-Pro Marketing on Wed, Nov. 05, 2025

Topics: contamination fluid cleanliness ISO Fluid Cleanliness Codes filter elements cleanoil hydraulic oil cleanliness hydraulic oil maintenance lubrication systems

5 min read

Is Your Oil Sample Accurate? Step-by-Step Procedures + Free Checklist

By Donaldson Hy-Pro Marketing on Wed, Sep. 17, 2025

Topics: contamination new oil fluid samples samples cleanoil oil handling best practices hydraulic oil cleanliness

8 min read

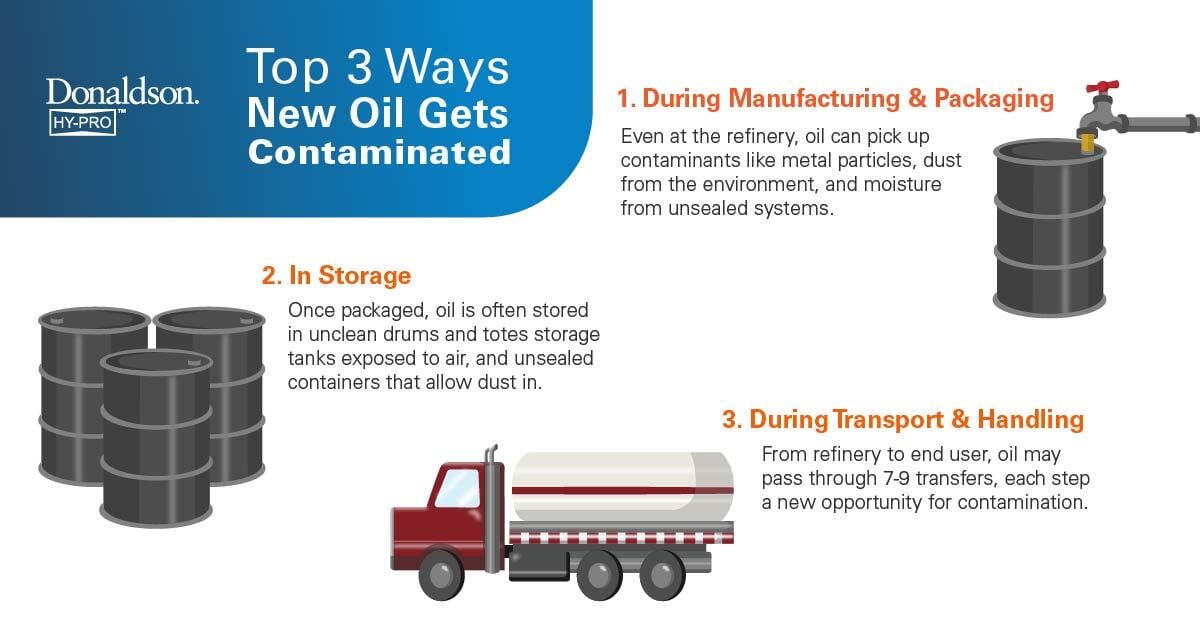

Is New Oil Clean? The Truth About Oil Contamination and How to Handle It

By Scott Howard on Mon, Sep. 08, 2025

Topics: contamination new oil cleanoil oil handling best practices hydraulic oil cleanliness

6 min read

How Dirt Makes Dirt: The Hidden Cost of Particulate Contamination

By Donaldson Hy-Pro Marketing on Wed, Apr. 16, 2025

Topics: dirt ISO Fluid Cleanliness Codes cutdirtcutcosts cleanoil

2 min read

Copper Mine Achieves Amazing Results with Donaldson Hy-Pro

By Hy-Pro Marketing on Tue, Jul. 23, 2024

Topics: ISO Fluid Cleanliness Codes case study cutdirtcutcosts cleanoil Copper Mine

3 min read

Hy-Pro Filtration Helps Paper Mill Achieve 75% Cleaner Oil

By Hy-Pro Marketing on Tue, Dec. 05, 2023

A new case study is available now!

With the help of Hy-Pro Filtration, a U.S. Paper Mill was able to achieve 75% cleaner oil.

Topics: ISO Fluid Cleanliness Codes case study paper mill cutdirtcutcosts cleanoil

1 min read

Updated Hy-Pro App Now Available

By Hy-Pro Marketing on Thu, May. 11, 2023

A new update is available for the Hy-Pro App!

Open this Blog to download below.

.png)

.png)

.png)

.png)

.png?width=750&height=288&name=Copper%20Mine%20Promo%20for%20Email%20(9).png)