Steel & Primary Metals

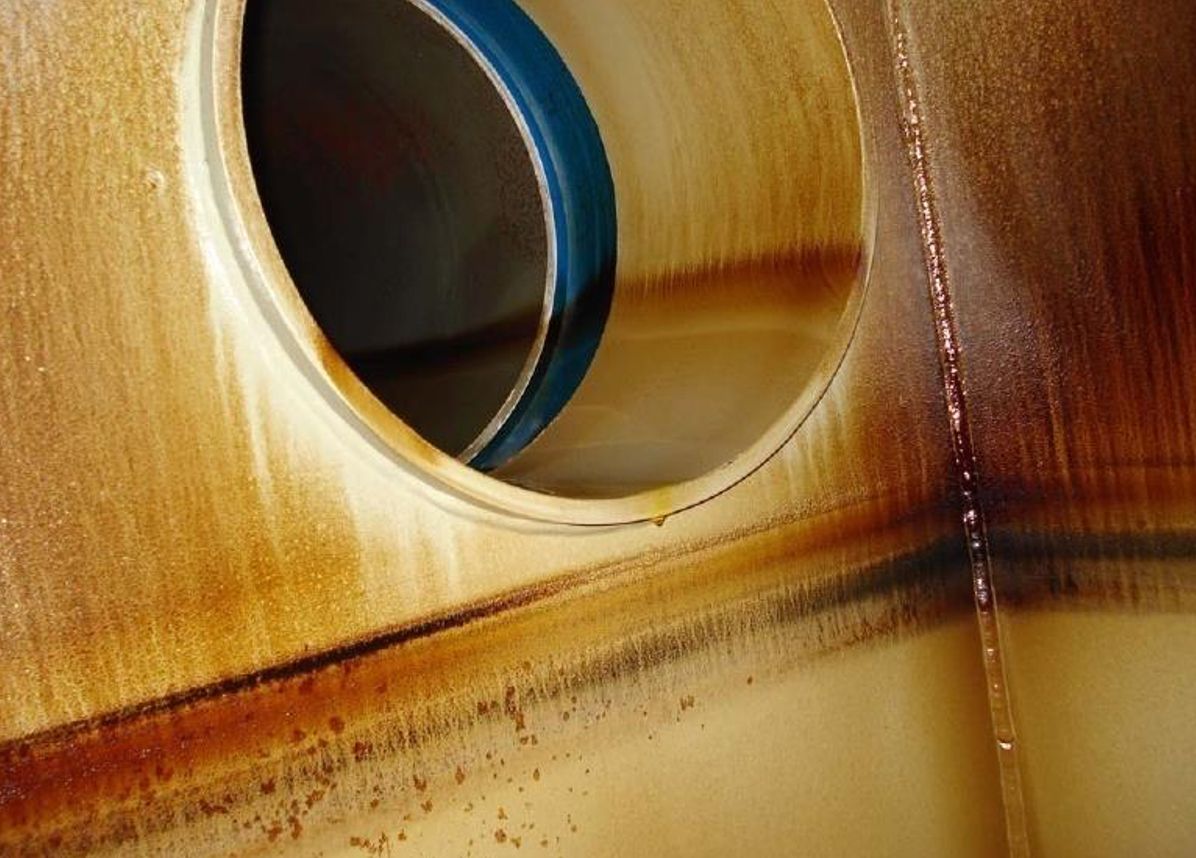

Hydraulic and lubrication system problems can cause millions of dollars in downtime and lost production for aluminum or steel mills. Further, as automatic gauge controls, roll bending, and other sophisticated systems become more common, servo-valve performance and reliability becomes more critical. Make Hy-pro a part of your lube team and we will implement strategies to significantly improve reliability of critical hydraulic systems in melt shops, continuous casters, and rolling mills, as well as processing operations downstream.