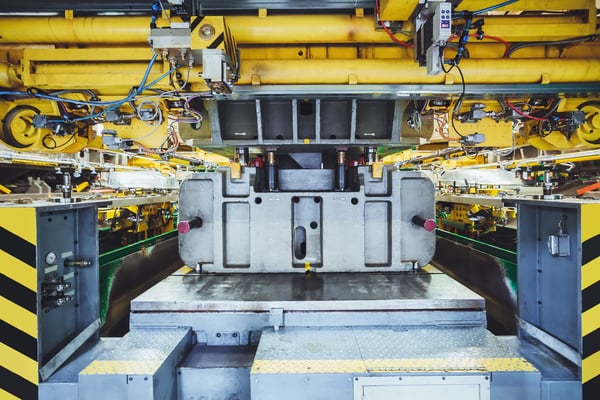

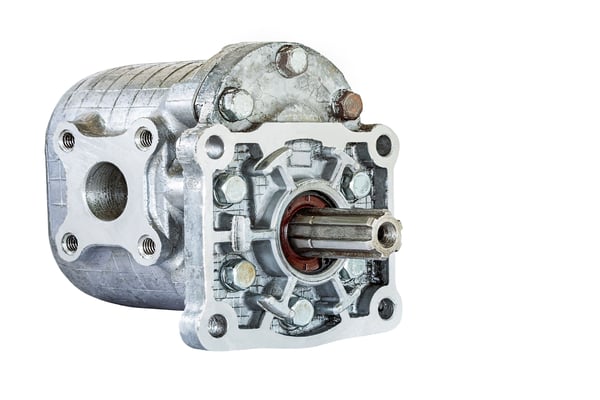

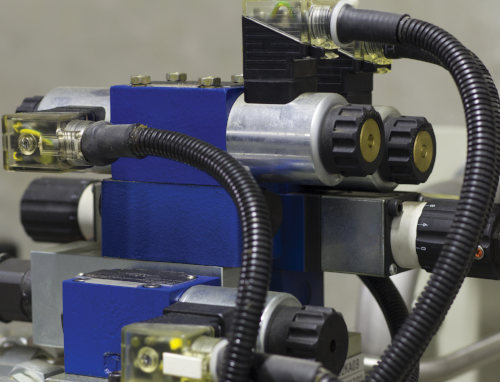

Modern diesel engines are more powerful, efficient, and cleaner than ever—yet many operators still face premature wear, rising maintenance costs, and unexpected downtime. The culprit is often overlooked: fuel that falls far short of the cleanliness levels today’s high-pressure fuel injectors require. This case study explores how one operation tackled fuel contamination head-on by implementing a targeted ISO cleanliness goal of 16/14/12 and deploying a strategic, three-stage filtration approach across storage tanks, dispensers, and equipment.

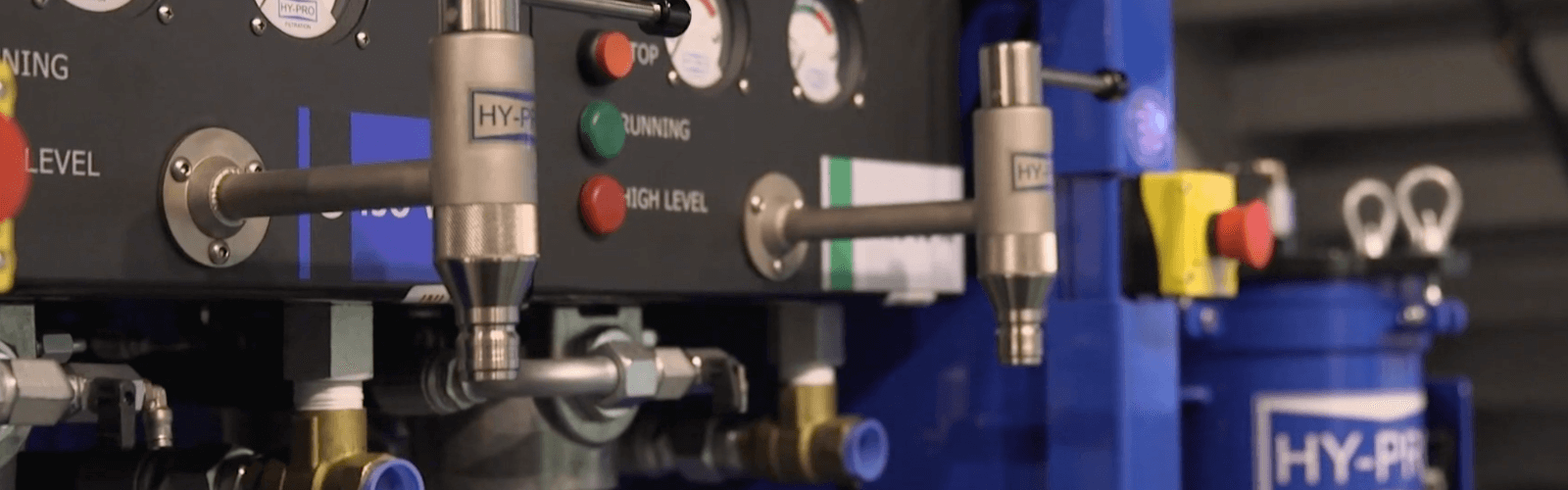

By filtering fuel to 1 micron before it ever reaches the engine—and retaining OEM filters as a final safeguard—the organization significantly extended injector life, reduced fuel dilution and filter replacements, and improved overall engine performance and efficiency. The results include measurable cost savings, lower emissions, and reduced waste-handling charges. This case study demonstrates how proactive fuel filtration not only protects advanced diesel systems but also unlocks the full potential of today’s engine technology.