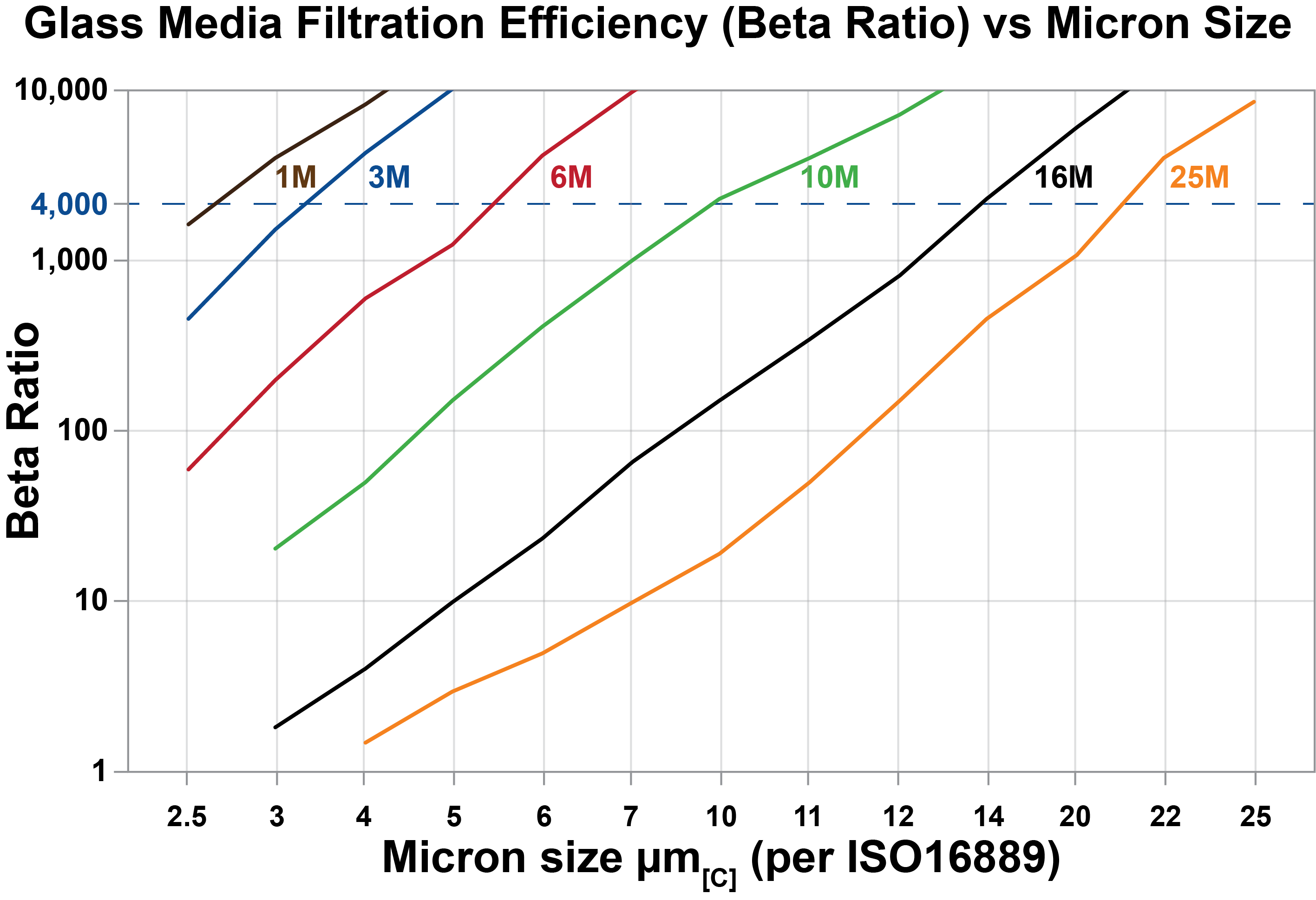

Hy-Pro's LF(M) High Viscosity Low Pressure Filter Assemblies are engineered to deliver superior filtration performance in high-flow hydraulic, high-viscosity lubrication, and heavily contaminated fuel applications. With a maximum operating pressure of 150 psi (10 bar) and options up to 1000 psi (68.9 bar), these assemblies ensure consistent fluid cleanliness and system reliability. Constructed from heavy-duty carbon steel or optional 304/316 stainless steel, the LF(M) series is built to withstand the toughest industrial conditions. Featuring oversized coreless filter elements with β3[C] > 4000 media efficiency, integral zero-leak bypass valves, and standard sample ports with true ΔP gauges, the LF(M) assemblies provide comprehensive monitoring and maintenance capabilities. Designed for seamless integration into existing systems, they offer flexibility and cost-effectiveness without the need for extensive modifications.

Max Operating Pressure: 150 psi (10 bar)

Available options up to 1000 psi (68.9 bar)

/LF36-18_052016.jpg)

/HP107L18%20High-CloseUp_2.jpg?width=410&name=HP107L18%20High-CloseUp_2.jpg)

/LFM22-2.jpg?width=330&name=LFM22-2.jpg)

/LFvessel-SamplePorts_051716.jpg?width=240&name=LFvessel-SamplePorts_051716.jpg)

/LFvessel-Top_051716.jpg?width=200&name=LFvessel-Top_051716.jpg)

/photo%202.jpg?width=338&name=photo%202.jpg)