Cut your filter usage and increase your uptime. (Yes, you read that correctly.)

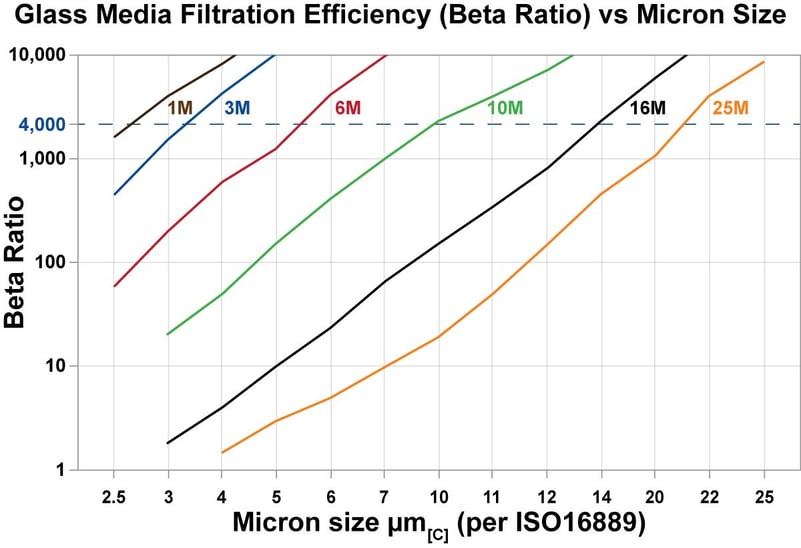

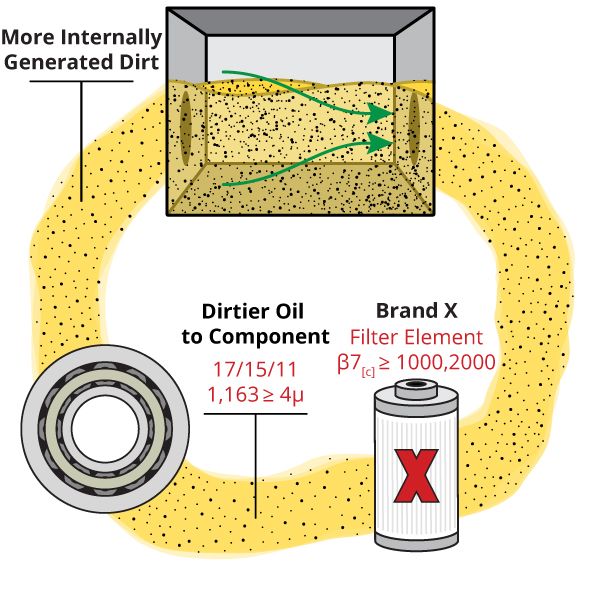

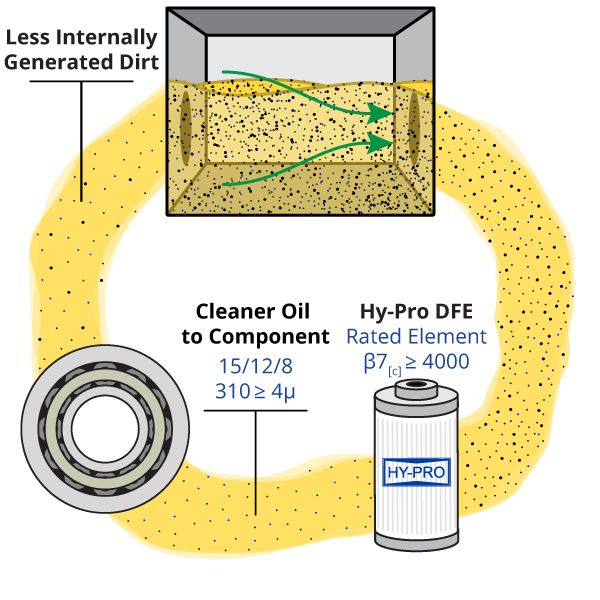

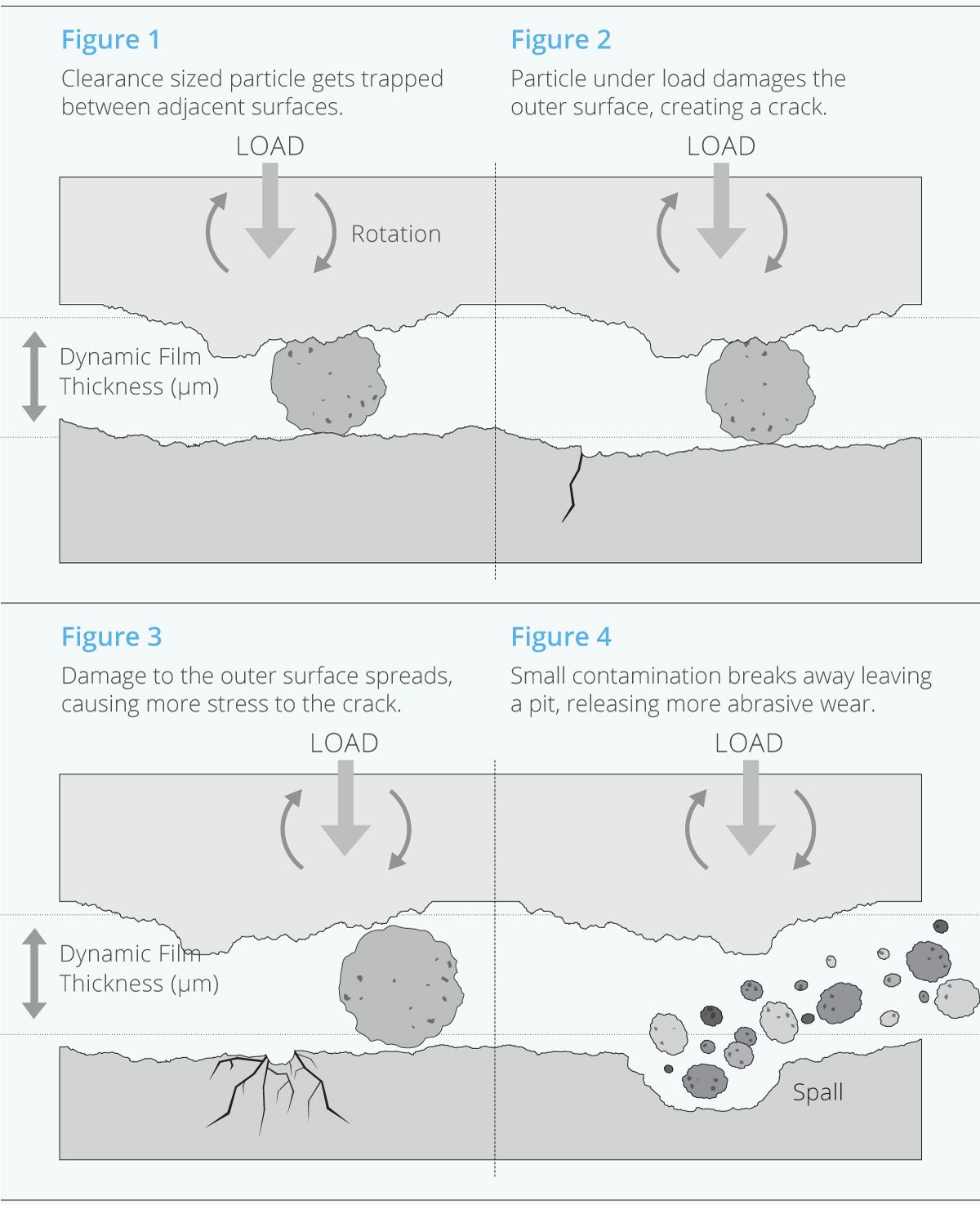

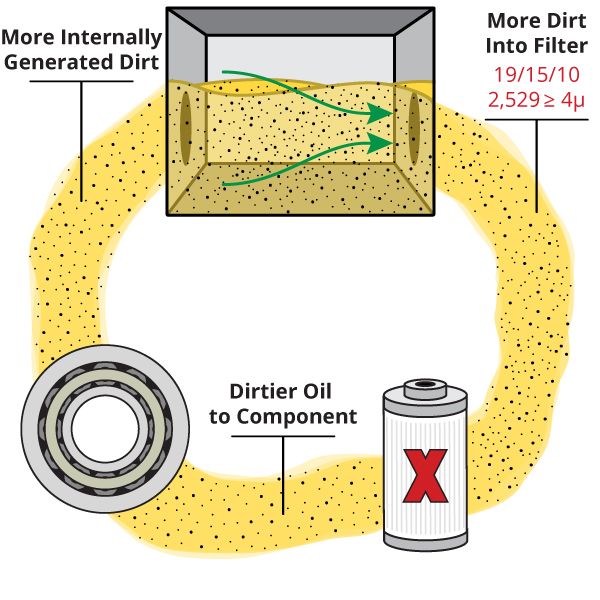

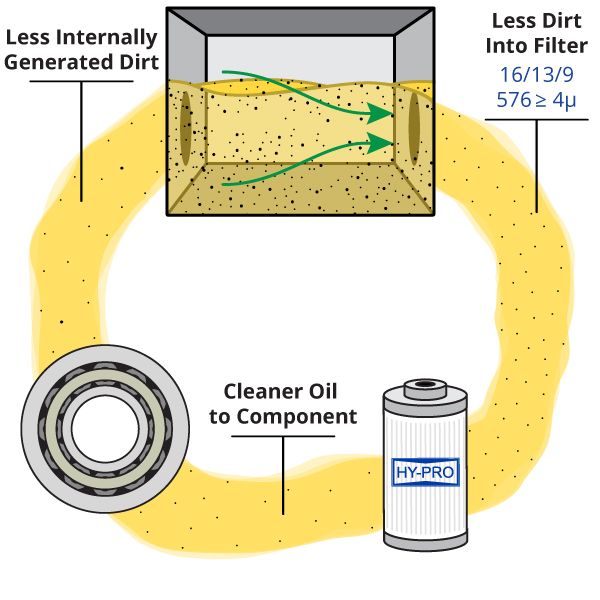

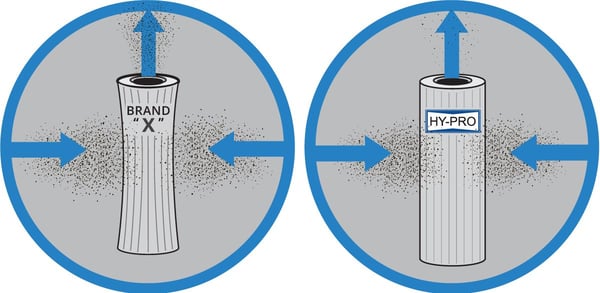

Hy-Pro filter element upgrades deliver the highest capture and retention efficiencies (βx[c] ≥ 4000) through advanced DFE rated element media and the removal of particles, water and oxidation byproducts, making Hy-Pro elements the one component in your critical systems that saves you money.

Hy-Pro’s advanced media technology is at the heart of our performance. DFE filter element construction goes beyond the lab and is field tested and proven to deliver cleaner oil in industry’s toughest applications, all the time.

We’ll prove it on your system

Together we help you achieve and maintain world class fluid cleanliness with solutions and strategies, sampling best practices, connected fluid monitoring, results interpretation, and condition based solutions all combined to give you cleaner oil and longer element life.