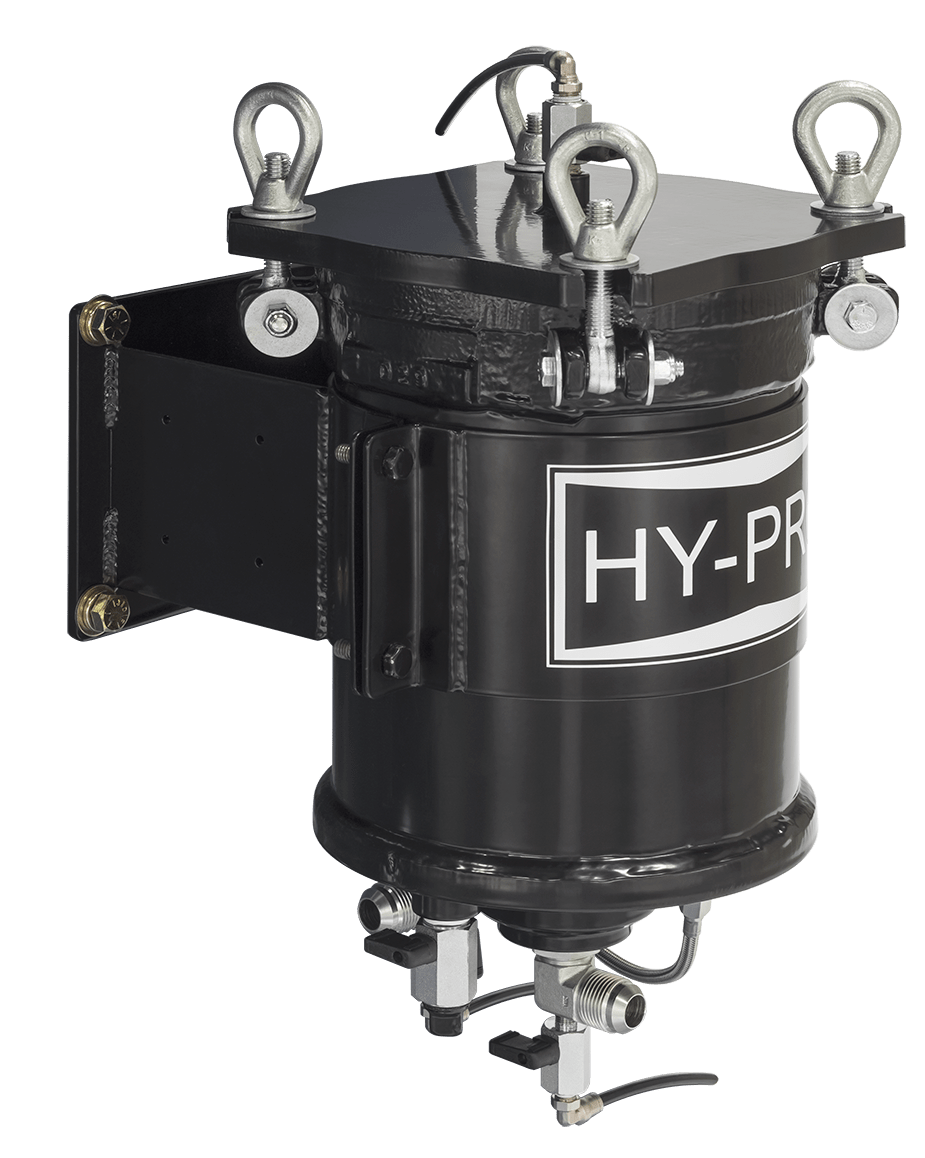

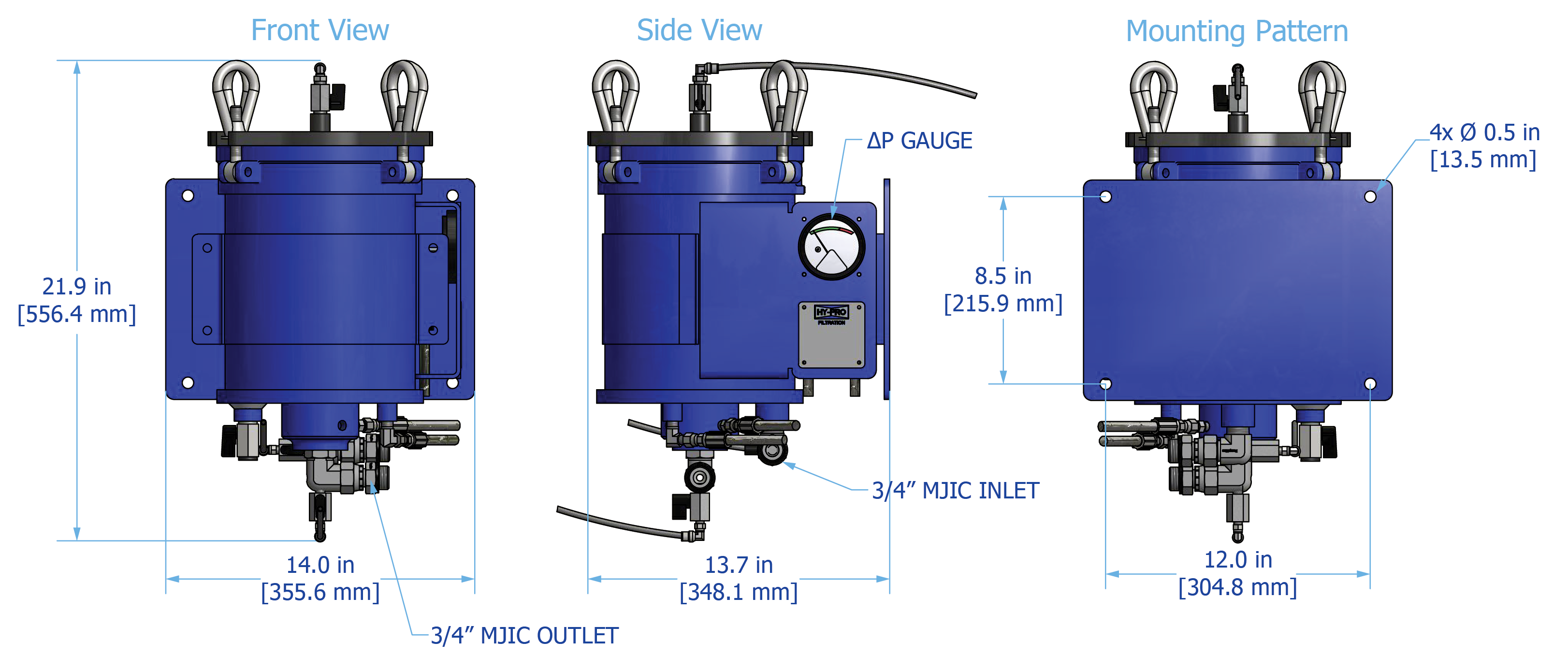

A compact, dedicated off-line contamination solution ideal for small reservoirs, gearboxes and diesel engine crankcase conditioning. Coming in at a whopping 0 ft2 of floor space, the LFW is designed to get your filtration off the ground and positioned conveniently for you, whether you’re polishing off that high viscosity gearbox oil or just want to add a little more protection for your critical components from heavy contaminants. And with Hy-Pro filter elements inside, the possibilities are endless for what you can do with the LFW.

Max Operating Pressure: 150 psi (10 bar)

Available options up to 250 psi (17.2 bar)