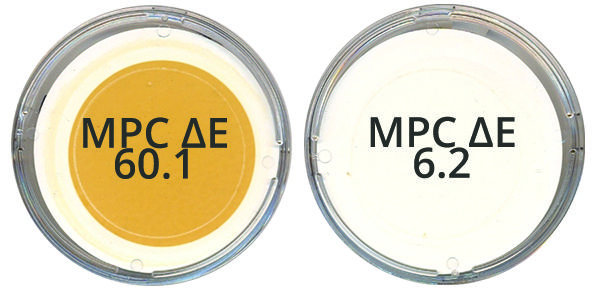

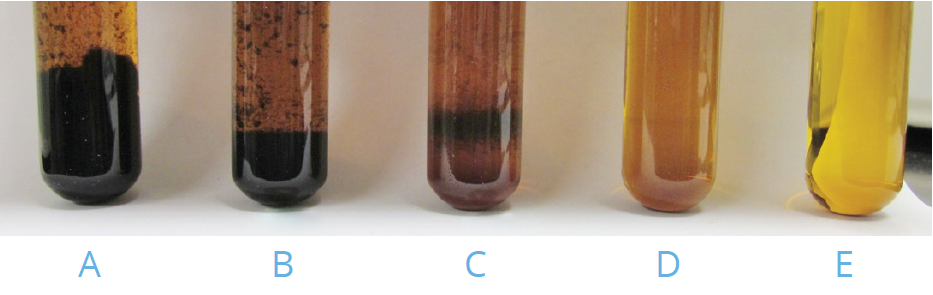

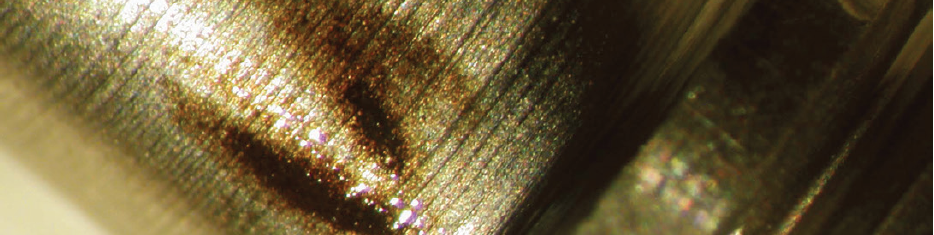

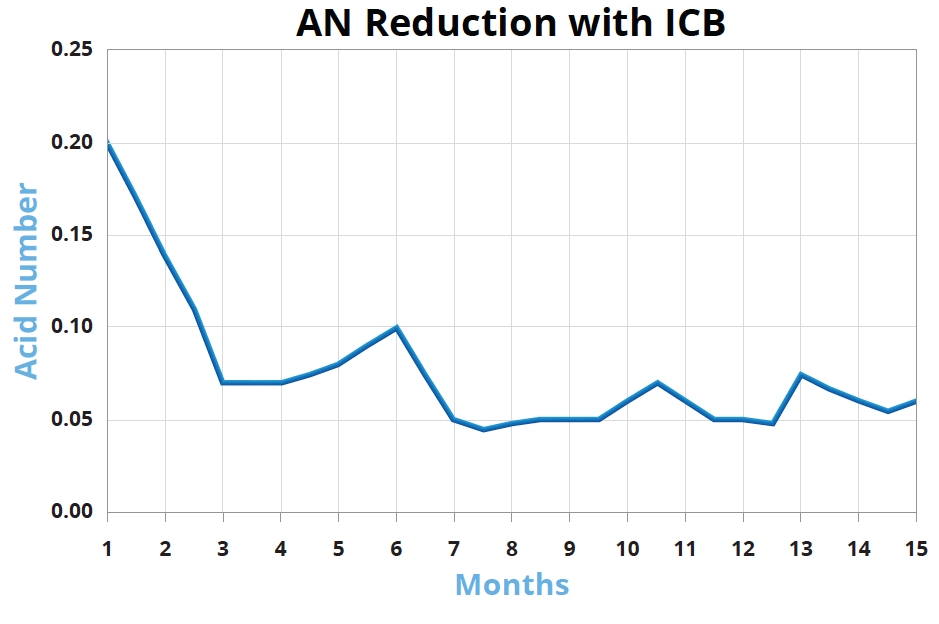

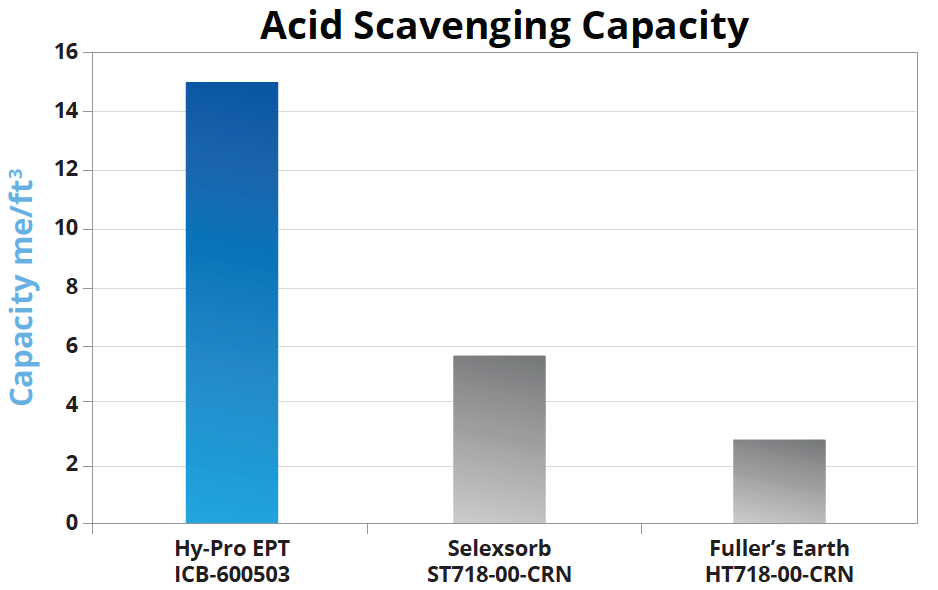

ICB® (Ion Charge Bonding) filter elements are engineered to eliminate the root causes of varnish, acidic byproducts, and dissolved metals in critical fluid systems, delivering best-in-class acid and varnish removal while helping protect servo valves from sticking or sluggish operation. Unlike conventional acid filters that leach metals or fine particles, ICB® elements help reverse oxidation processes on a molecular level, restore oil health, and improve fluid resistivity to support efficient, trouble-free system performance.

*ICB® is a registered trademark of EPT CLEAN OIL.