- Products

- Industry Solutions

- Cement Plants

- Aluminum Processing

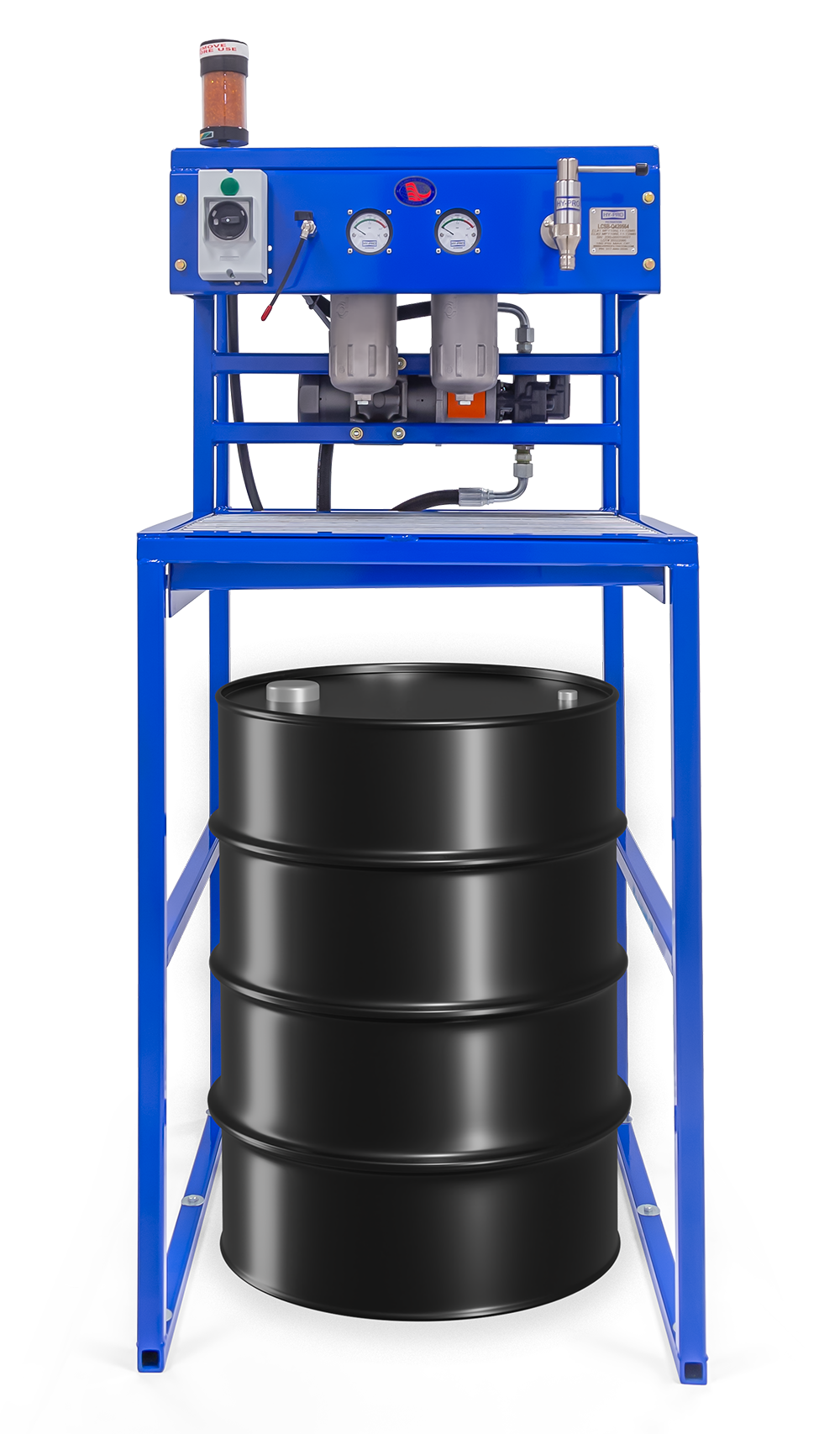

- Bulk Oil & Fuel Conditioning

- Diesel Fuel Conditioning

- Fluid Reclamation

- Gearbox Filtration

- Mining

- Oil Refinery & Petrochemical

- Paper Mill

- Phosphate Ester Fluid Solutions

- Plastic Injection Molding

- Power Generation

- Steel Mill

- Varnish Solutions

- Wind Turbines

- Wood Products

- Resources

- About