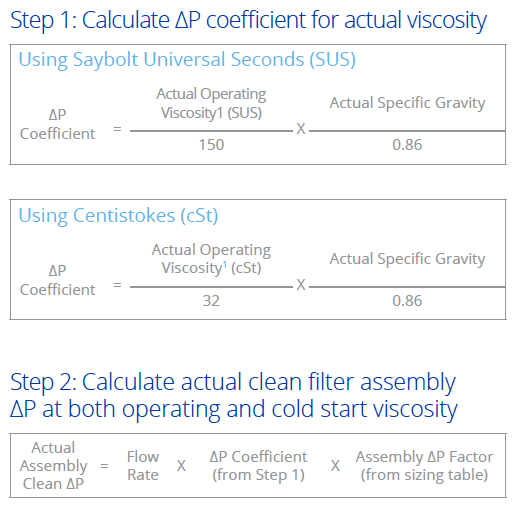

Filter Assembly Sizing Guidelines

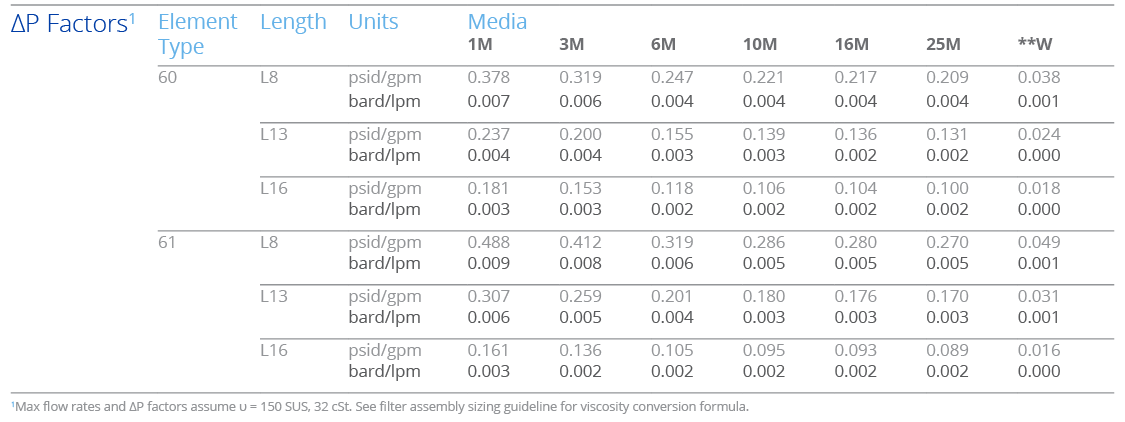

Effective filter sizing requires consideration of flow rate, viscosity (operating and cold start), fluid type and degree of filtration. When properly sized, bypass during cold start can be avoided/minimized and optimum element efficiency and life achieved. The filter assembly differential pressure values provided for sizing differ for each media code, and assume 32 cSt (150 SUS) viscosity and 0.86 fluid specific gravity. Use the following steps to calculate clean element assembly pressure drop.

Sizing recommendations to optimize performance and permit future flexibility

• To avoid or minimize bypass during cold start the actual assembly clean ΔP calculation should be repeated

for start-up conditions if cold starts are frequent.

• Actual assembly clean ΔP should not exceed 10% of bypass ∆P gauge/indicator set point at normal operating viscosity.

• If suitable assembly size is approaching the upper limit of the recommended flow rate at the desired degree of filtration consider increasing the assembly to the next larger size if a finer degree of filtration might be preferred in the future. This practice allows the future flexibility to enhance fluid cleanliness without compromising clean ΔP or filter element life.

• Once a suitable filter assembly size is determined consider increasing the assembly to the next larger size to optimize filter element life and avoid bypass during cold start.

• When using water glycol or other specified synthetics, we recommend increasing the filter assembly by 1~2 sizes.