In our last post, Improving Rolling Mill Oil with Vacuum Dehydration, we discussed how the

Dirty, Emulsified Oil = Stressed Bearings

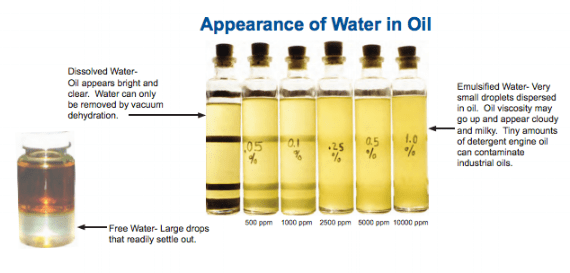

Steel rolling mill lube oil systems commonly have high water contamination, which requires daily decanting of free water. However, when

Rolling mill lube is typically dirty with only pleated wire mesh filters or strainer baskets in place to address particles. It is common for ISO codes in rolling mill lube oil to be 22/20/18 and higher. High levels of particulate contamination can affect the

Save Your Bearings, Save Your Oil

Instead of accepting dirty and emulsified oil as a part of steel mill life, many of Hy-Pro’s steel customers have installed the VUD vacuum dehydrator to remove free, emulsified and dissolved water eliminating the need for decanting. This change reduces roll stand leakage, slashes oil consumption and eliminates contamination bearing failures. The VUD is also fitted with a high-efficiency DFE rated filter element that removes particles

In our next post, we'll discuss specifics about real-world results with vacuum dehydrators.