Contamination is Complicated; Removing it is Easy

Check out our latest product explainer video on Hy-Pro's VUD

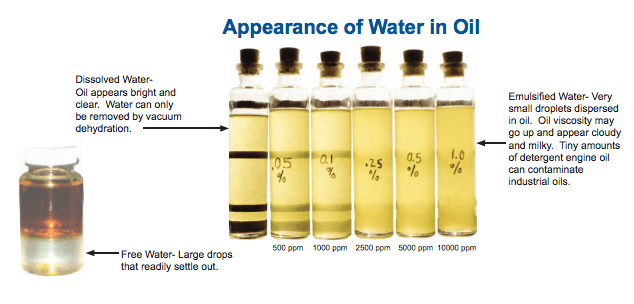

The optimized balance between heat, vacuum, process design, and an easy, user-friendly operating system for removal of water and particulate from hydraulic and high viscosity lubricating oils. Equipped with generously sized, high-efficiency filtration, the VUD is the ultimate oil purifier. Keeping fluids clean and dry extends component and bearing life, increases productivity, minimizes downtime, and extends useful fluid life. The VUD is ideal for removing all forms of water, including free, emulsified, and dissolved water and gas from hydraulic and lubricating oils.