Dirt is a silent killer of your equipment.

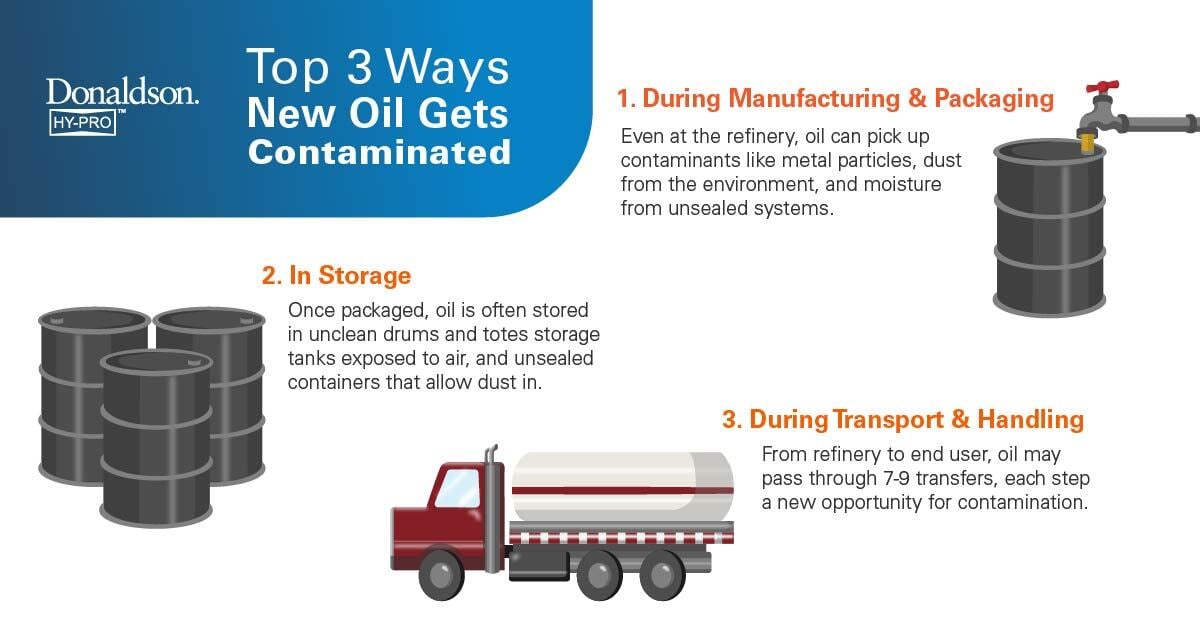

Did you know that as much as 75% of equipment downtime can be attributed to particulate contamination? These tiny intruders can infiltrate your system at any stage, from manufacturing to maintenance, wreaking havoc on your machinery equipment or system.

How Particulate Contamination Accelerates Wear

Once dirt finds its way into your system, it becomes a self-perpetuating problem. As oil flows through your equipment, it carries contaminants, causing abrasion and generating even more debris. This vicious cycle not only shortens the lifespan of your filters and oil but puts your entire system at risk.

To break this cycle and safeguard your equipment, investing in high-efficiency filter elements for filtration is crucial. We also recommend pre-filtering your oil before introducing it to your system, so you can significantly reduce the initial contamination load. This proactive measure allows you to maintain a low operating ISO code, ensuring optimal performance and longevity.

Best Practices for Contamination Prevention in Hydraulic Systems

Beyond filtration, implementing these simple practices can further minimize contamination.

-

Cleanliness is Key: Before any maintenance or repair, create a clean workspace by removing debris and temporarily halting airflow.

-

Proper Oil Handling: Store drained oil in a designated container for cleaning and reuse.

-

Careful Maintenance: Use lint-free rags and keep filter elements covered to prevent contamination during handling.

Long-Term Benefits of Contamination Prevention for Equipment Performance

By prioritizing contamination prevention and adopting high-efficiency filtration throughout your system, you can reap numerous rewards.

-

Reduced Downtime: Less dirt means less wear and tear, leading to fewer breakdowns and extended equipment life.

-

Lower Filtration Costs: Overall system cleanliness combined with high-quality filters can last longer, reducing the frequency of replacements.

-

Improved System Performance: Clean systems operate more efficiently, saving energy and boosting productivity.

Additionally, this could potentially extend oil life, saving money and assisting with your sustainability goals.

Don't let dirt sabotage your operations. By taking proactive steps to prevent contamination and adopting a high-efficiency filtration strategy using Donaldson Hy-Pro filter elements, you can help protect your equipment, minimize downtime, and maximize your bottom line.

FAQ: Contamination Prevention & Hydraulic System Filtration

Q: What is particulate contamination and how does it affect equipment?

Particulate contamination consists of dirt, metal shavings, and other debris that enter hydraulic systems. It causes abrasion, accelerates wear, and can lead to costly downtime.

Q: How can I prevent contamination in my hydraulic system?

Use high-efficiency filter elements, pre-filter oil before use, maintain a clean workspace, and handle oil and filters carefully.

Q: What are the benefits of high-efficiency filter elements?

High-efficiency filters can help reduce particulate levels, extend oil and filter life, improve equipment performance, and lower overall maintenance costs.

Q: How does maintaining a low ISO code improve performance?

A low ISO code indicates cleaner oil, which helps to reduces wear on equipment components, improves reliability, and maximizes productivity.

Q: Can contamination prevention extend oil life?

Yes. Keeping oil clean with proper filtration and handling can reduce degradation and extend the usable life of your oil.

About Donaldson Hy-Pro:

Donaldson Hy-Pro offers a wide range of hydraulic filtration solutions that can help you improve the performance of your machinery. Our filter elements are designed to combat dirt, water, and oxidation by-products, so you can keep your systems running at peak performance.

If you're looking for a way to reduce filter expenses, improve oil cleanliness, and extend the life of your equipment, Donaldson Hy-Pro can help. Contact us today to learn more.