Dynamic Filter Efficiency

What is Dynamic Filter Efficiency?

Dynamic Filter Efficiency matches filter testing with real-life conditions.

All hydraulic and lube systems have a critical contamination tolerance level that is often defined by, but not limited to, the most sensitive system component such as servo valves or high speed journal bearings. Defining the ISO fluid cleanliness code upper limit is a function of component sensitivity, safety, system criticality and ultimately getting the most our of hydraulic and lube assets.

Filters remove the particulate contamination that enters a system or is generated by the system as it operates. All filters are subjected to some form of system dynamics: hydraulic filters encounter frequent and rapid changes in flow rate when valves shift, cylinders unload and pump output changes; lube filters experience dynamic conditions during start up and shut down. Filters validated only to current ISO testing standards don't perform as expected when subjected to the demands of real world dynamic operating systems.

A filter is not a black hole. Two key characteristics of filter performance are capture efficiency and retention efficiency. Capture efficiency can be thought of simply as how effectively a filter captures particles while retention efficiency is a measure of how effectively that filter retains the particles it has captured. A filter is not a black hole, and its performance must not be based solely on how efficiently it captures particles. If not properly designed and applied, a filter can become one of the most damaging sources of contamination in a system if it releases previously captured particles when challenged with dynamic conditions.

The Dynamic Filter Efficiency Test (DFE) is the evolution of standard hydraulic and lube filter performance testing, DFE goes further than current industry standards to quantify, capture, and retention efficiency in real time by inducing dynamic duty cycles, measuring real-time performance during dynamic changes and the filters ability to retain particles. DFE testing is the method for predicting worst case fluid cleanliness along with average fluid cleanliness. The DFE test method was pioneered in 1998 during a joint effort between Scientific Services Inc (SSI) and Hy-Pro Filtration.

Current Filter Performance Testing Methods

Check out this video that explains in-depth current multi-pass testing methods.

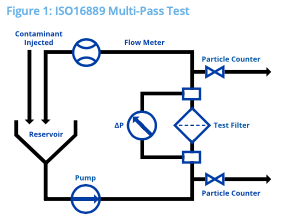

To understand the need for DFE it is important to understand how filters are currently tested and validated. Manufacturers use the industry standard ISO16889 multi-pass test to rate filter efficiency and dirt holding capacity of filter elements under ideal lab conditions.

Figure 1 depicts the test circuit where hydraulic fluid is circulated at a constant flow rate in a closed loop system with on-line particle counters before and after the test filter. Contaminated fluid is added to the system at a constant rate. Small amounts of fluid are removed before and after the filter for particle counting to calculate the filter efficiency (capture). The capture efficiency is expressed as the Filtration Ratio (Beta) which is the relationship between the number of particles greater than and equal to a specified size (micron) counted before and after the filter. In real world terms this test is the equivalent of testing a filter in an off-line kidney loop rather than replicating an actual hydraulic or lube system. It's basically a filter cart test.

at a constant flow rate in a closed loop system with on-line particle counters before and after the test filter. Contaminated fluid is added to the system at a constant rate. Small amounts of fluid are removed before and after the filter for particle counting to calculate the filter efficiency (capture). The capture efficiency is expressed as the Filtration Ratio (Beta) which is the relationship between the number of particles greater than and equal to a specified size (micron) counted before and after the filter. In real world terms this test is the equivalent of testing a filter in an off-line kidney loop rather than replicating an actual hydraulic or lube system. It's basically a filter cart test.

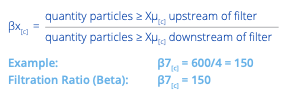

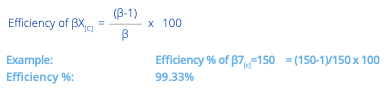

Filtration Ration (Beta) per ISO16889:

In the example above, 600 particles greater than or equal to 7µ[c] were counted upstream of the filter and 4 were counted downstream. This Filtration Ratio is expressed as "Beta 7[c] = 150". The [c] is referred to as "sub c". The sub c is used to differentiate between multi-pass tests run per the current ISO16889 multi-pass test with new particle counter calibration per ISO11171 from ISO4572. Filtration Ratio expressed or written without the "sub c" refers to the antiquated ISO4572 multi-pass test superseded by ISO16889. The efficiency may also be expressed as a percentage by converting the Filtration Ratio:

Using our Beta Ratio found in the first example, we can calculate that the test filter is 99.33% efficient at capturing particles at 7µ[c] or larger.

The Dynamic Filter Efficiency Testing Method

DFE multi-pass enhances the industry standard by inducing dynamic conditions (duty cycle) and measuring the effects of the duty cycle in real time instead of looking at normalized numbers over a time weighted average. DFE also quantifies retention efficiency in real time in order to identify a filter's ability to properly retain previously captured contaminant and the degree to which it unloads captured contaminant back into the system. For an easy comparison, think of it as a sneeze that releases a rush of contamination to levels that are well above the upper limit of fluid cleanliness then fades as the flow rate normalizes.

In the DFE test, flow rate is truly dynamic in that rapid changes can be made while maintaining full system flow through the test filter. The raw data is continuously collected and organized so filter efficiency can be reported for variable flow conditions including time weighted averages and isolated moments to reveal true filter performance during hydraulic stress conditions - exactly when you need the filter to perform at its best.

At the end of the initial test when the filter element is loaded with contaminant, it is subjected to a restart test in which the flow goes from zero to max flow in milliseconds, replicating a hydraulic or lube system restart. Through rapid particle counting with precise control, this dynamic flow change allows Hy-Pro to analyze the amount of particles released and understand both the capture and retention efficiencies of each and every filter tested.

Get in touch with us here at Hy-Pro Filtration by emailing info@hyprofiltration.com.

Want to learn more about Multi-Pass Testing and DFE testing? Check out these videos to get the best understanding of todays most relevant testing methods.

Getting to Know Multi-Pass Testing Part 1

Getting to Know Multi-Pass Testing Part 2

Interested in testing your ISO Codes onsite? Download this brochure to see what we recommend.