2 min read

Factory Side Chat Podcast, Episode 9, Reducing the Total Cost of Ownership with a Kidney Loop or Offline Filtration unit

By Hy-Pro Marketing on Fri, Aug. 26, 2022

Topics: fluid cleanliness ISO Fluid Cleanliness Codes cleanliness hydraulic oil Podcast Factoryside Chat Podcast cutdirtcutcosts kidney loop

2 min read

Factory Side Chat Podcast, Episode 8, Partners for Life

By Hy-Pro Marketing on Thu, Jun. 02, 2022

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, Podbean, and YouTube.

Topics: fluid cleanliness cleanliness hydraulic oil filter elements Podcast Factoryside Chat Podcast cutdirtcutcosts partners for life

5 min read

Dynamic Filter Efficiency

By Hy-Pro Marketing on Thu, Mar. 18, 2021

Dynamic Filter Efficiency

What is Dynamic Filter Efficiency?

Dynamic Filter Efficiency matches filter testing with real-life conditions.

All hydraulic and lube systems have a critical contamination tolerance level that is often defined by, but not limited to, the most sensitive system component such as servo valves or high speed journal bearings. Defining the ISO fluid cleanliness code upper limit is a function of component sensitivity, safety, system criticality and ultimately getting the most our of hydraulic and lube assets.

Topics: varnish in hydraulic oil vacuum dehydration mining fluid samples total systems cleanliness metal analysis coalesce technology cleanliness COD lube oil turbine oil glass media demulsibility servo valves

3 min read

Understanding ISO Codes

By Hy-Pro Marketing on Thu, Feb. 25, 2021

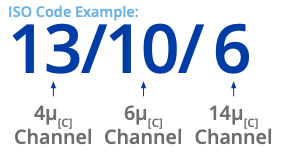

ISO Cleanliness Codes Explained

The ISO Cleanliness Code (per ISO4406-1999) is used to quantify particulate contamination levels per milliliter of fluid at 3 sizes - 4µ, 6µ, and 14µ. It is expressed in 3 numbers (example 19/17/14) where each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. For a detailed breakdown and a handy ISO code cheat sheet, see our ISO Code Guide & Cheat Sheet It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

Topics: hydraulic fluid dirt hydraulic filters Gearbox filtration vacuum dehydration filter housing sizing plastic injection molding manufacturer oil darkening mining fluid samples total systems cleanliness metal analysis filter performance paper mill fluid transfer filters hydraulic valve coalesce technology filter cart cleanliness COD hydraulic oil gearbox duplex high-pressure compressor filter elements lube oil turbine oil desiccant demulsibility

1 min read

Removing Water from Diesel; Hy-Pro's Coalescing Technology

By Hy-Pro Marketing on Wed, Mar. 25, 2020

In this Video we provide a brief description and demonstration of Hy-Pro's signature coalescing technology found in our FCLCOD and COT model lines.