The Dynamic Filtration Efficiency (DFE) Test is Hy-Pro's standard for testing filter elements. Throughout this four-part

First, let's start with the basics.

Why are filters used? How are they rated?

All hydraulic and lube systems have a critical contamination tolerance level that is often defined by -- but not limited to -- the most sensitive system component such as servo valves or high-speed journal bearings. Defining the ISO fluid cleanliness code upper limit is a function of component sensitivity, safety, system criticality and ultimately getting the most out of hydraulic and lube assets.

All hydraulic and lube systems have a critical contamination tolerance level that is often defined by -- but not limited to -- the most sensitive system component such as servo valves or high-speed journal bearings. Defining the ISO fluid cleanliness code upper limit is a function of component sensitivity, safety, system criticality and ultimately getting the most out of hydraulic and lube assets.

Filters remove the particulate contamination that enters a system or is generated by the system as it operates. All filters are subjected to some form of system dynamics: hydraulic filters encounter frequent and rapid changes in flow rate when valves shift, cylinders unload and pump output changes; lube filters experience dynamic conditions during startup and shut down. Filters validated only to current ISO testing standards don’t perform as expected when subjected to the demands of real-world dynamic operating systems.

Measuring Filter Performance: Capture Efficiency

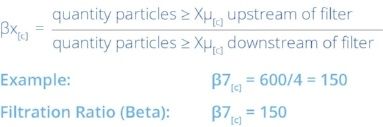

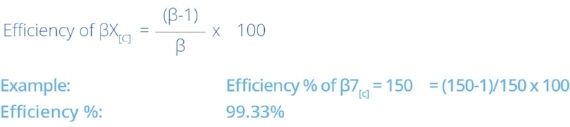

Capture efficiency is a measure of how effectively a filter captures particles. It is defined in terms of Filtration (Beta) Ratio per ISO16889 and is recorded during the ISO16889 multi-pass test used by most filter manufacturers.

In the example, 600 particles greater than or equal to 7μ[c] were counted upstream of the filter and 4 were counted downstream. This Filtration Ratio is expressed as “Beta 7[c] = 150”. The [c] is referred to as “sub c”. The sub c is used to differentiate between multi-pass tests run per the current ISO16889 multi-pass test with new particle counter calibration per ISO11171 from ISO4572. Filtration Ratio expressed or written without the “sub c” refers to the antiquated ISO4572 multi-pass test superseded by ISO16889. The efficiency may also be expressed as a percentage by converting the Filtration Ratio

Measuring Filter Performance: Retention Efficiency

Retention efficiency is a measure of how effectively a filter retains the particles it has captured. It can be determined by comparing a filter’s Filtration (Beta) Ratio during constant flow rate, increases in flow rate and decreases in flow rate. It is not recorded during the ISO16889 multi-pass test used by most filter manufacturers.

A filter is not a black hole, and its performance must not be based solely on how efficiently it captures particles. If not properly designed and applied, a filter can become one of the most damaging sources of contamination as it will release previously captured particles when challenged with dynamic conditions.

The lack of a method to test filters under varied flow rates led to the development of The Dynamic Filter Efficiency Test (DFE) in 1998 as a joint effort between Scientific Services Inc. (SSI) and Hy-Pro Filtration. DFE is the evolution of standard hydraulic and lube filter performance testing. DFE goes further than current industry standards to quantify capture and retention efficiency in real time by inducing dynamic duty cycles, measuring real-time performance during dynamic changes and the filters ability to retain particles. DFE testing is the method for predicting worst case fluid cleanliness along with average fluid cleanliness.

Stay tuned. Next week we’ll discuss both

test methods and their differences more in-depth.