9 min read

Understanding ISO 4406 Cleanliness Codes: A Complete Guide to Fluid Contamination and Reliability

By Donaldson Hy-Pro Marketing on Wed, Dec. 03, 2025

Topics: contamination fluid cleanliness ISO Fluid Cleanliness Codes filter elements cleanoil hydraulic oil cleanliness hydraulic oil maintenance lubrication systems

2 min read

24-Hour Turnaround: How Clean Oil Restored Production at a U.S. Paper Mill

By Donaldson Hy-Pro Marketing on Wed, Nov. 05, 2025

Topics: contamination fluid cleanliness ISO Fluid Cleanliness Codes filter elements cleanoil hydraulic oil cleanliness hydraulic oil maintenance lubrication systems

2 min read

Factory Side Chat Podcast, Episode 8, Partners for Life

By Hy-Pro Marketing on Thu, Jun. 02, 2022

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, Podbean, and YouTube.

Topics: fluid cleanliness cleanliness hydraulic oil filter elements Podcast Factoryside Chat Podcast cutdirtcutcosts partners for life

2 min read

Factory Side Chat Podcast Episode 7 Filter Sizing and Selection

By Hy-Pro Marketing on Sat, Jan. 29, 2022

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, Podbean, and YouTube.

Topics: filter housing sizing filters filter sizing filter elements Podcast Factoryside Chat Podcast

3 min read

Getting to Know Demulsibility

By Hy-Pro Marketing on Thu, Mar. 25, 2021

Demulsibility

What is Demulsibility?

Demulsibility is the ability of oil to separate from water. Oil and water naturally separate because like molecules attract each other. Oil sticks with oil, water sticks with water. Oil is "hydrophobic", or "afraid of water," which is a benefit when it comes to fluids like turbine oil.

Topics: varnish in hydraulic oil varnish in turbine oil contamination water in oil dirt Phosphate Ester diesel engine maintenance steel mills vacuum dehydration rolling mill lubricating oil filter housing sizing micro-dieseling thermal event ISO 4406 vacuum dehydrator fluid samples oil analysis metal analysis paper mill hydraulic pump samples COD duplex low-pressure gearbox contaminination hydraulic duplex high-pressure cellulose media filter elements filter comparison aluminum refinery lab

4 min read

Fluid Life Extension

By Hy-Pro Marketing on Thu, Mar. 11, 2021

Extending Fluid Life Saves Money and Helps the Environment

Our mission is to make our customers as efficient as possible, and we achieve that with the highest quality filtration products and total system cleanliness strategies to maximize uptime, productivity and prevent costly fluid contamination related failures. Been there. Done that. Going to do it again tomorrow. But that's not the only way we make our customers efficient. Extending the useful life of in-service fluids pays big dividends in reliability, saves money on premature fluid replacement costs, and reduces the environmental impact of industry by reducing the amount of fluids used and discarded. Enhancing reliability, saving money, and protecting the environment are not only good business, they're our responsibility. To help reduce oil usage, let's first understand why fluids are condemned and prematurely replaced.

Topics: varnish in hydraulic oil hydraulic fluid dirt vacuum dehydration filter housing sizing oil darkening mining fluid samples oil analysis filter performance paper mill fluid transfer filters filter cart gearbox LCS duplex high-pressure indianapolis filter elements lube oil turbine oil desiccant demulsibility

3 min read

Understanding ISO Codes

By Hy-Pro Marketing on Thu, Feb. 25, 2021

ISO Cleanliness Codes Explained

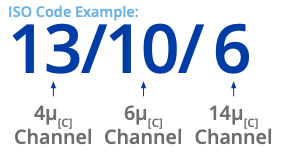

The ISO Cleanliness Code (per ISO4406-1999) is used to quantify particulate contamination levels per milliliter of fluid at 3 sizes - 4µ, 6µ, and 14µ. It is expressed in 3 numbers (example 19/17/14) where each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. For a detailed breakdown and a handy ISO code cheat sheet, see our ISO Code Guide & Cheat Sheet It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

Topics: hydraulic fluid dirt hydraulic filters Gearbox filtration vacuum dehydration filter housing sizing plastic injection molding manufacturer oil darkening mining fluid samples total systems cleanliness metal analysis filter performance paper mill fluid transfer filters hydraulic valve coalesce technology filter cart cleanliness COD hydraulic oil gearbox duplex high-pressure compressor filter elements lube oil turbine oil desiccant demulsibility

4 min read

Parsing Filter Media and Filter Element Types

By Hy-Pro Marketing on Thu, Feb. 01, 2018

In the fascinating and fundamental field that is industrial fluid filtration, there exist many types of filter elements and many different types of media. In this article, we will briefly cover filter elements and the most common types of media they're made up of. The medias featured below include: cellulose, glass, wire mesh and water removal, coalesce and resin.

Topics: contamination filtration filter elements

3 min read

DFE: Testing Filters Under Real-Life Conditions (Part 4 of 4)

By Hy-Pro Marketing on Tue, Jul. 18, 2017

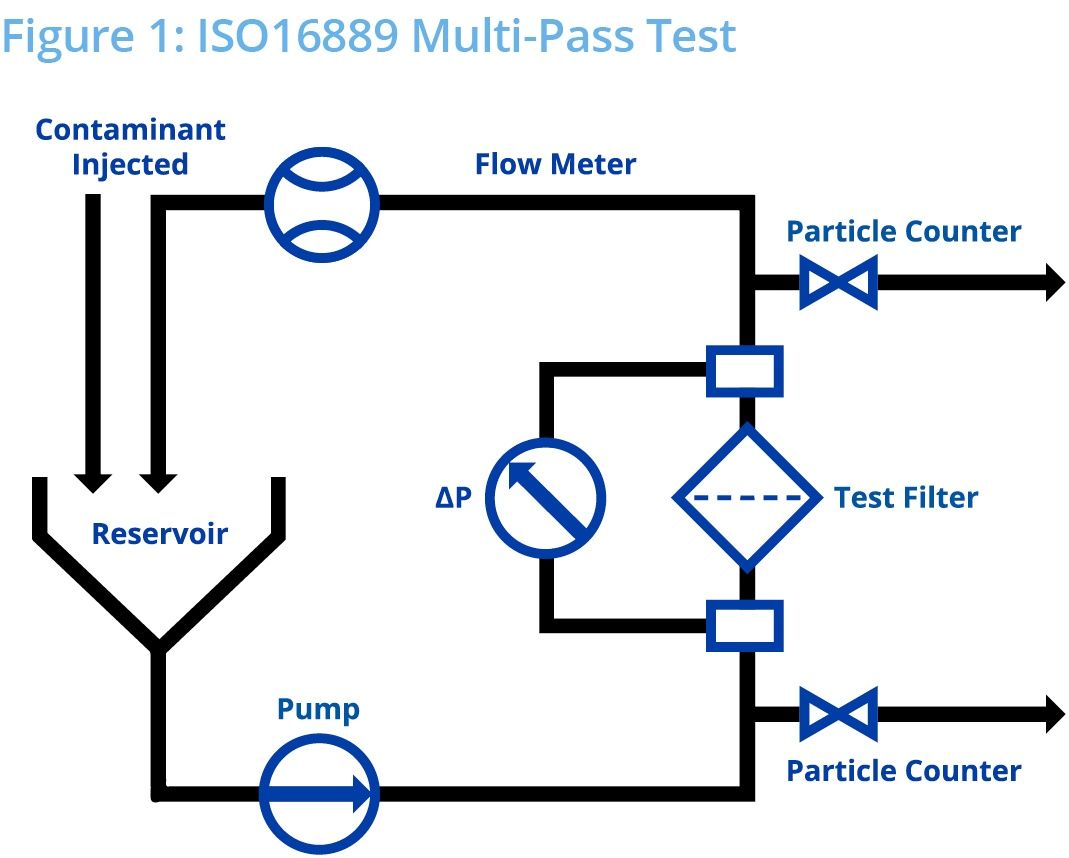

Throughout the first three entries in this series (find parts one, two and three), we've discussed the difference in two filter element testing methods, ISO16889 and DFE. We've also illustrated how many elements fall short of their stated beta ratio under dynamic flow conditions. Today we'll wrap it up with simulated cold-start tests.

DFE Multi-Pass: Cold Start Contamination Retention

Once the element has captured enough contaminant to reach approximately 90% of the terminal ΔP (dirty filter indicator setting), the main flow goes to zero and the injection system is turned off for a short dwell period. Then the main flow goes to maximum element rated flow accompanied by real-time particle count to measure retention efficiency of the contaminant loaded element. The dynamic duty cycle is repeated to further monitor the retention efficiency of the filter element after a restart.

Topics: ISO 16889 case study filter performance filter elements

4 min read

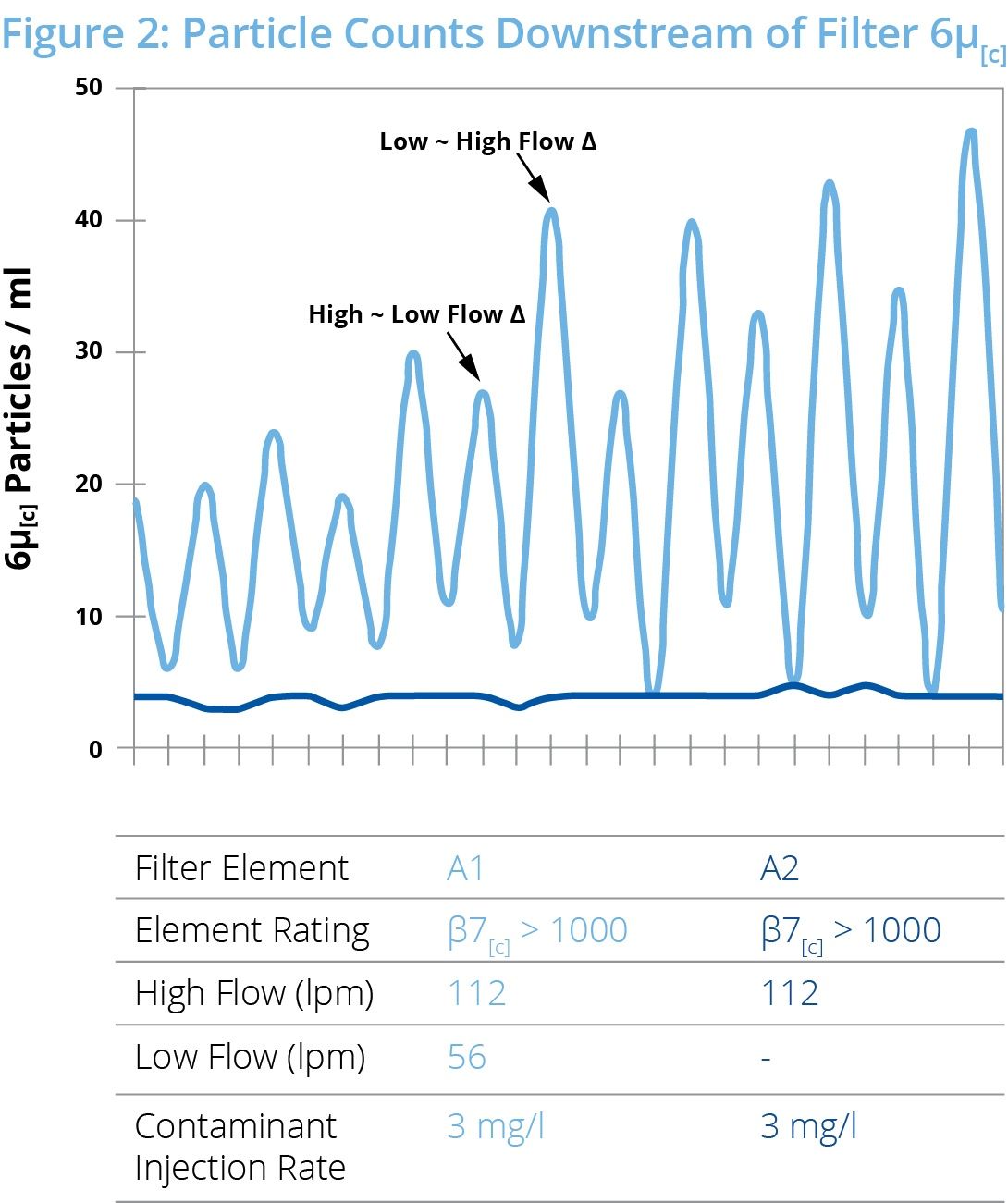

DFE: Testing Filters Under Real-Life Conditions (Part 3 of 4)

By Hy-Pro Marketing on Tue, Jul. 11, 2017

Last week we covered the differences between the ISO16889 Filter Test Procedure and the DFE Filter Test Procedure. This week we illustrate the difference between elements engineered to retain particles during dynamic flow conditions and those that are engineered only to pass the ISO16889 test. (Looking for previous posts? Find parts one, two and four.)

.png)

.png)