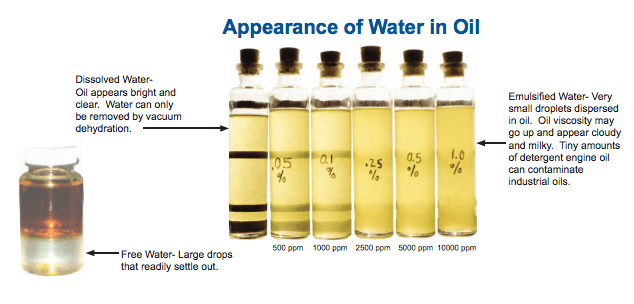

Water is a compound that is required for practically everything on the earth. But within a lubrication or hydraulic system, it's one of the most damaging contaminants possible. Unfortunately, it's also one of the most common contaminants you'll find in your system.

2 min read

Hydraulic Oil Water Removal

By Hy-Pro Marketing on Wed, Nov. 14, 2012

Topics: water Water Contamination hydraulic oil contaminination

8 min read

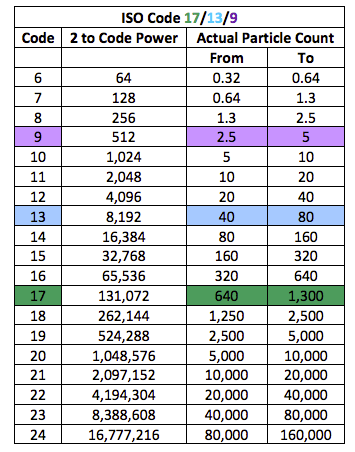

ISO 4406: What Do Those Numbers Mean in the ISO Cleanliness Codes?

By Hy-Pro Marketing on Mon, Oct. 08, 2012

Guest post today by Dan Helgerson. He is the Technical Editor of the Fluid Power Journal, where this article was originally published.

We have been talking a lot about filtration here at the steel mill. My predecessor had done a remarkable job in educating by example, demonstrating the need for good control of the fluids in our hydraulic and lubrication systems. He had helped stop the leaks and had added well-thought-out filtration systems that have resulted in substantial savings and increased productivity.

There is still a lot of work to be done and in pursuing that we have invited a number of vendors in, each offering an approach to getting and maintaining an acceptable fluid cleanliness level. The one thing that they all have brought to the table is a discussion of the ISO Cleanliness code. I was in a meeting with a group of managers when one vendor began to talk about the code. Being a Certified Fluid Power Accredited Instructor (AI), I immediately saw this as an obvious teaching moment, so I asked, “Does anyone here want to know what those numbers mean?” The answer was a quick and resounding, “No!”

Topics: iso cleanliness codes ISO 4406

4 min read

Glass or Cellulose Filter Media?

By Hy-Pro Marketing on Mon, Sep. 17, 2012

Glass or Cellulose: Which Hydraulic Filter Media is Best?

There are several distinct differences between glass and cellulose media. Media selection should be based on the required cleanliness and other unique needs of the system. Evaluate the Beta ratio (efficiency), dirt holding capacity, flow versus pressure drop characteristics, etc. A hydraulic filter supplier should be able to supply more detailed test information in addition to what is supplied in the literature.

Cellulose vs. Glass: Absolute and Nominal Filter Efficiency

Normally, wire mesh and cellulose media elements are nominally rated, which means they might be only 50% efficient at the rated micron size. Most glass media elements are considered to be “absolute” rated which means that they are 99.5% efficient at the rated micron size. Check the Beta ratio before selecting the media as all “

Elements of different media with the same “micron rating” can have substantially different filtration efficiency. The graphic below provides a visual representation of the difference between absolute and nominal filter efficiency.

The illustrated glass element would typically deliver an ISO Fluid Cleanliness Code of 18/15/8 to 15/13/9 or better depending upon the system conditions and ingression rate. The cellulose element would typically achieve a code no better than 22/20/17.

Cellulose vs. Glass: Fibers and Cleaning

Runaway contamination levels at 4μ[c] and 6μ[c] are very common when cellulose media is applied where a high population of fine particles exponentially generate more particles in a chain reaction of internally generated contaminate.

Inorganic glass fibers are much more uniform in diameter and are smaller than cellulose fibers. Organic cellulose fibers can be unpredictable in size and effective useful life. Smaller fiber size means more fibers and more void volume space to capture and retain contaminate.

Topics: hydraulic fluid ISO 16889 cellulose media filter elements filter comparison glass media

2 min read

Vacuum Dehydrator VUD: Real-World Results

By Hy-Pro Marketing on Mon, Sep. 10, 2012

Hy-Pro Vacuum Dehydrators Improve Mill Reliability

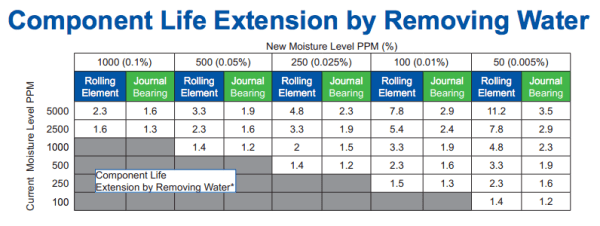

We Hy-Pro Vacuum Dehydrators already know that maintaining low levels of water in rolling mill lubricating oil can help improve uptime, extend oil life, prevent bearing failures and increase profitability. But, what about an actual example of how a vacuum dehydrator has improved mill reliability?

Topics: vacuum dehydrator total systems cleanliness

2 min read

Oil Vacuum Dehydrators: Managing Water in Rolling Mill Lubricating Oil

By Hy-Pro Marketing on Fri, Aug. 31, 2012

In our last post, Improving Rolling Mill Oil with Vacuum Dehydration, we discussed how the

Topics: hydraulic fluid contamination water Water Contamination rolling mill lubricating oil vacuum dehydrator VUD

2 min read

Improving Rolling Mill Lubricant Oil with Vacuum Dehydration

By Hy-Pro Marketing on Tue, Aug. 07, 2012

Benefits of Vacuum Dehydration for Rolling Mill Lubricant Oil

Steel mills typically use lubricants with high