2 min read

Factory Side Chat Podcast, Episode 9, Reducing the Total Cost of Ownership with a Kidney Loop or Offline Filtration unit

By Hy-Pro Marketing on Fri, Aug. 26, 2022

Topics: fluid cleanliness ISO Fluid Cleanliness Codes cleanliness hydraulic oil Podcast Factoryside Chat Podcast cutdirtcutcosts kidney loop

2 min read

Factory Side Chat Podcast, Episode 8, Partners for Life

By Hy-Pro Marketing on Thu, Jun. 02, 2022

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, Podbean, and YouTube.

Topics: fluid cleanliness cleanliness hydraulic oil filter elements Podcast Factoryside Chat Podcast cutdirtcutcosts partners for life

3 min read

Understanding ISO Codes

By Hy-Pro Marketing on Thu, Feb. 25, 2021

ISO Cleanliness Codes Explained

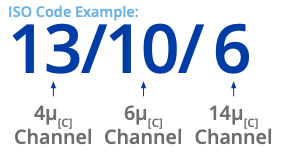

The ISO Cleanliness Code (per ISO4406-1999) is used to quantify particulate contamination levels per milliliter of fluid at 3 sizes - 4µ, 6µ, and 14µ. It is expressed in 3 numbers (example 19/17/14) where each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. For a detailed breakdown and a handy ISO code cheat sheet, see our ISO Code Guide & Cheat Sheet It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

Topics: hydraulic fluid dirt hydraulic filters Gearbox filtration vacuum dehydration filter housing sizing plastic injection molding manufacturer oil darkening mining fluid samples total systems cleanliness metal analysis filter performance paper mill fluid transfer filters hydraulic valve coalesce technology filter cart cleanliness COD hydraulic oil gearbox duplex high-pressure compressor filter elements lube oil turbine oil desiccant demulsibility

2 min read

Hydraulic Valve Performance Test Stands and Clean Oil

By Hy-Pro Marketing on Tue, Nov. 29, 2016

The Application

A hydraulic valve manufacturer required pristine fluid (< 14/12/9) to test flow across an 80-micron orifice on their test stand. Gross amounts of contamination in the fluid would skew the test results, invalidating any data collected.

The system held 100 l (26.4

Topics: ISO 4406 hydraulic valve samples hydraulic oil

3 min read

Why You Need to Care About Micro-Dieseling

By Scott Howard on Mon, Jan. 27, 2014

Most people are familiar with diesel engines and how they work, which includes a rapid compression of air. When you inject a fuel source, it creates an explosion. Did you know that micro-dieseling is similar? A front-end loader that runs a diesel engine is a macro-level (or big picture) of what it does on the micro (or smaller) level in a hydraulic pump.

Topics: diesel thermal event fuel hydraulic oil contaminination

2 min read

Hydraulic Oil Water Removal

By Hy-Pro Marketing on Wed, Nov. 14, 2012

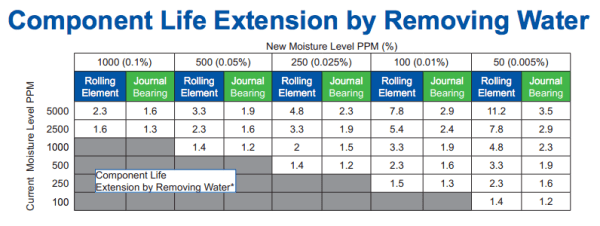

Water is a compound that is required for practically everything on the earth. But within a lubrication or hydraulic system, it's one of the most damaging contaminants possible. Unfortunately, it's also one of the most common contaminants you'll find in your system.