Last week, in part one, we briefly discussed how filter elements are rated by manufacturers. This week we're discussing the industry standard ISO16889 multi-pass test and Hy-Pro's standard, the DFE test. (Already read part two? Read parts three and four.)

Current Filter Performance Testing Methods

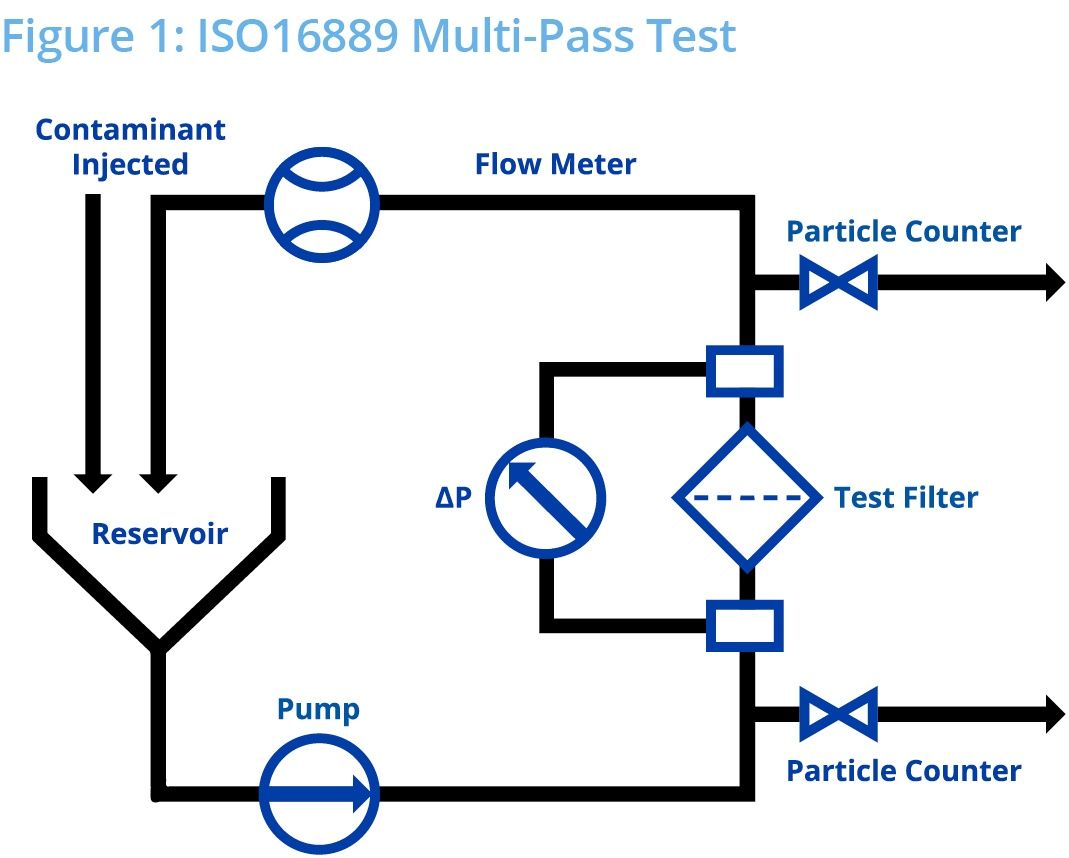

To understand the need for DFE, it is important to understand how filters are currently tested and validated. Manufacturers use the industry standard ISO16889 multi-pass test to rate filter efficiency and dirt-holding capacity of filter elements under ideal lab conditions.

Figure 1 depicts the test circuit where hydraulic fluid is circulated at a constant flow rate in a closed-loop system with on-line particle counters before and after the test filter. Contaminated fluid is added to the system at a constant rate. Small amounts of fluid are removed before and after the