Controlling the contaminant flow of your hydraulic, lubricant or fuel reservoirs is one of the simplest goals in achieving Total Systems Cleanliness.

3 min read

Breathers: An Essential Part of Total System Cleanliness

By Hy-Pro Marketing on Wed, Feb. 21, 2018

Topics: contamination total systems cleanliness breathers

4 min read

Parsing Filter Media and Filter Element Types

By Hy-Pro Marketing on Thu, Feb. 01, 2018

In the fascinating and fundamental field that is industrial fluid filtration, there exist many types of filter elements and many different types of media. In this article, we will briefly cover filter elements and the most common types of media they're made up of. The medias featured below include: cellulose, glass, wire mesh and water removal, coalesce and resin.

Topics: contamination filtration filter elements

2 min read

How Clean is New Oil? Part 2

By Hy-Pro Marketing on Mon, Apr. 15, 2013

Previously, we discussed how new oil picks up contamination on its way to your facility. Let's take a look at a three more reasons your new oil continues to be contaminated as it reaches your distributor.

Topics: contamination new oil liquid conditioning station LCS

2 min read

How Clean is New Oil? Part 1

By Hy-Pro Marketing on Tue, Apr. 09, 2013

Lubricants and hydraulic oil have to go a long way to make it into your system, which means there's a high potential for it to pick up particulate and water at every step along the way.

Around here at Hy-Pro, we cringe when we think about that process and how our customers put that oil into their machines. We want you to be aware of the state of the oil that you're using, so let's take a look at three reasons why new oil does not mean CLEAN oil.

Topics: contamination new oil liquid conditioning station LCS

1 min read

Improving Rolling Mill Lube Oil Performance and Useful Life - Part 3: Solution

By Hy-Pro Marketing on Mon, Mar. 18, 2013

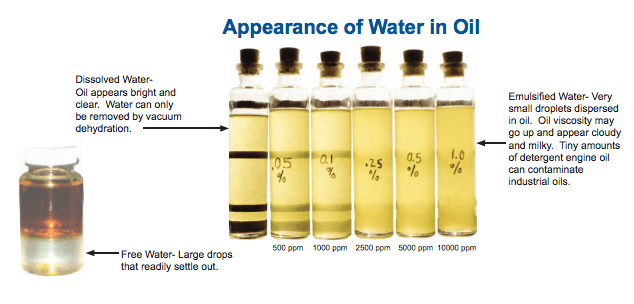

At the end of Part 2, we discussed the winning nature of vacuum dehydration. If you missed Part 1 in the series, you can find it here.

At the end of Part 2, we discussed the winning nature of vacuum dehydration. If you missed Part 1 in the series, you can find it here.

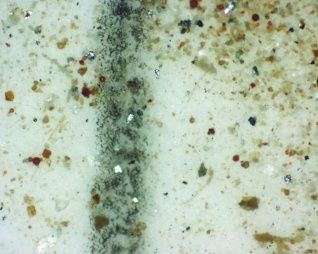

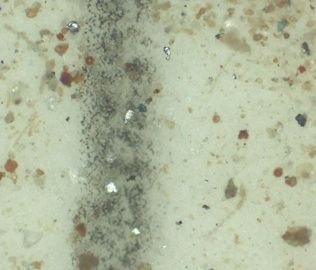

Did you know that hydrogen is the friendliest molecule - meaning that it is most likely seeking partners to attach to? Similarly, the suspended particles in oil actively look for particles to join forces, so they pair with the water.

This particulate contamination is the catalyst guilty of continuing the degradation of the oil and the increase of emulsified water. The more water there is, the more oxidation that occurrs. This also increases various acids that form as the molecules break down. These acids attack seals, hoses, pumps and metal.

Topics: contamination iso cleanliness codes steel mills rolling mill lubricating oil vacuum dehydrator

2 min read

Improving Rolling Mill Lube Oil Performance and Useful Life - Part 2: Prevention

By Hy-Pro Marketing on Fri, Feb. 22, 2013

If you're just tuning in and didn't catch the first part of our steel mill and lube oil series, click here.

When we left off, we just determined how the high levels of emulsified water and high particulate contamination levels work together to cause bearing failure and reduce oil life. So, how do we prevent this expensive combination from happening? We're glad you asked!

Topics: contamination iso cleanliness codes steel mills rolling mill lubricating oil oil mills vacuum dehydrator

2 min read

Improving Rolling Mill Lube Oil Performance and Useful Life - Part 1: Quality

By Hy-Pro Marketing on Fri, Feb. 15, 2013

Premium oils keep steel mills running. It's crucial to protect their quality in order to keep the mills fully functioning.

In both hot and cold steel mill production, high-demulsibility lubricant is used for backup roller bearing lubrication. Some of these oils are referred to as SD, which stands for super-demulsibility. Not surprisingly, these SD oils are a premium product and come at a premium price. If a manufacturer wants to invest in these big-ticket oils, they obviously want to go to great lengths in order to keep them clean and fully functioning.

Join us for this three-part series as we take an in-depth look at improving rolling mill lube oil performance and useful life.

Topics: contamination iso cleanliness codes steel mills vacuum dehydrator

1 min read

Keeping Clean in a Dirty Environment [Case Study]

By Hy-Pro Marketing on Fri, Feb. 08, 2013

Mining is a dirty business, as you can imagine, and equipment used to aid in mining efforts is not immune to the filth. Yet it is imperative to keep fluid clean. Not only will it save time and money, it lessens the amount of downtime for repairs, which is always a great goal.

Topics: contamination case study hydraulic

1 min read

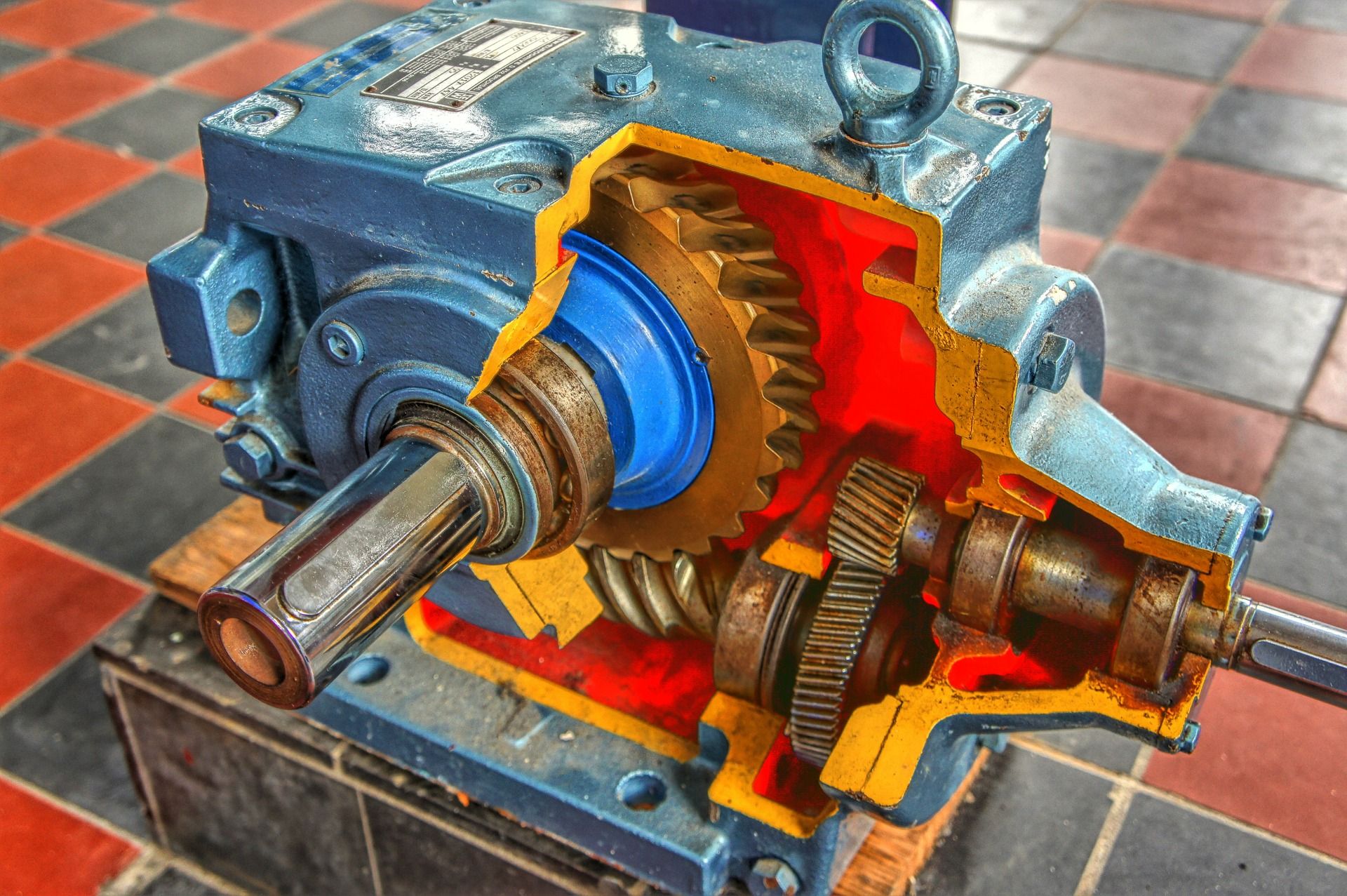

How to Prevent Gearbox Failure

By Hy-Pro Marketing on Thu, Jan. 17, 2013

When gearboxes go down, it’s generally because of contamination. This is a costly repair on its own, but once you include the loss of production from downtime, the cost can soar to astronomical figures. Sadly, though, sometimes gearbox failure happens, which wastes your time and money. Let’s take a look at some of the main causes of gearbox contamination and how you can prevent it.

Topics: contamination breathers gearbox

2 min read

Oil Vacuum Dehydrators: Managing Water in Rolling Mill Lubricating Oil

By Hy-Pro Marketing on Fri, Aug. 31, 2012

In our last post, Improving Rolling Mill Oil with Vacuum Dehydration, we discussed how the