Extending Fluid Life Saves Money and Helps the Environment

Our mission is to make our customers as efficient as possible, and we achieve that with the highest quality filtration products and total system cleanliness strategies to maximize uptime, productivity and prevent costly fluid contamination related failures. Been there. Done that. Going to do it again tomorrow. But that's not the only way we make our customers efficient. Extending the useful life of in-service fluids pays big dividends in reliability, saves money on premature fluid replacement costs, and reduces the environmental impact of industry by reducing the amount of fluids used and discarded. Enhancing reliability, saving money, and protecting the environment are not only good business, they're our responsibility. To help reduce oil usage, let's first understand why fluids are condemned and prematurely replaced.

to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

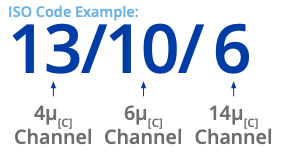

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.