3 min read

Hy-Pro Filtration Helps Paper Mill Achieve 75% Cleaner Oil

By Hy-Pro Marketing on Tue, Dec. 05, 2023

Topics: ISO Fluid Cleanliness Codes case study paper mill cutdirtcutcosts cleanoil

3 min read

Getting to Know Demulsibility

By Hy-Pro Marketing on Thu, Mar. 25, 2021

Demulsibility

What is Demulsibility?

Demulsibility is the ability of oil to separate from water. Oil and water naturally separate because like molecules attract each other. Oil sticks with oil, water sticks with water. Oil is "hydrophobic", or "afraid of water," which is a benefit when it comes to fluids like turbine oil.

Topics: varnish in hydraulic oil varnish in turbine oil contamination water in oil dirt Phosphate Ester diesel engine maintenance steel mills vacuum dehydration rolling mill lubricating oil filter housing sizing micro-dieseling thermal event ISO 4406 vacuum dehydrator fluid samples oil analysis metal analysis paper mill hydraulic pump samples COD duplex low-pressure gearbox contaminination hydraulic duplex high-pressure cellulose media filter elements filter comparison aluminum refinery lab

4 min read

Fluid Life Extension

By Hy-Pro Marketing on Thu, Mar. 11, 2021

Extending Fluid Life Saves Money and Helps the Environment

Our mission is to make our customers as efficient as possible, and we achieve that with the highest quality filtration products and total system cleanliness strategies to maximize uptime, productivity and prevent costly fluid contamination related failures. Been there. Done that. Going to do it again tomorrow. But that's not the only way we make our customers efficient. Extending the useful life of in-service fluids pays big dividends in reliability, saves money on premature fluid replacement costs, and reduces the environmental impact of industry by reducing the amount of fluids used and discarded. Enhancing reliability, saving money, and protecting the environment are not only good business, they're our responsibility. To help reduce oil usage, let's first understand why fluids are condemned and prematurely replaced.

Topics: varnish in hydraulic oil hydraulic fluid dirt vacuum dehydration filter housing sizing oil darkening mining fluid samples oil analysis filter performance paper mill fluid transfer filters filter cart gearbox LCS duplex high-pressure indianapolis filter elements lube oil turbine oil desiccant demulsibility

3 min read

Understanding ISO Codes

By Hy-Pro Marketing on Thu, Feb. 25, 2021

ISO Cleanliness Codes Explained

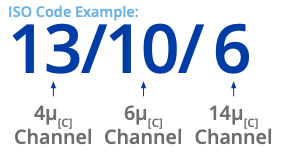

The ISO Cleanliness Code (per ISO4406-1999) is used to quantify particulate contamination levels per milliliter of fluid at 3 sizes - 4µ, 6µ, and 14µ. It is expressed in 3 numbers (example 19/17/14) where each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. For a detailed breakdown and a handy ISO code cheat sheet, see our ISO Code Guide & Cheat Sheet It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.