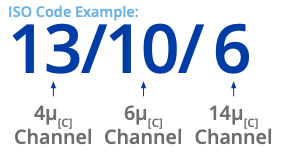

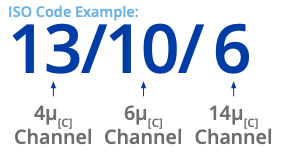

ISO Cleanliness Codes Explained

The ISO Cleanliness Code (per ISO4406-1999) is used to quantify particulate contamination levels per milliliter of fluid at 3 sizes - 4µ, 6µ, and 14µ. It is expressed in 3 numbers (example 19/17/14) where each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. For a detailed breakdown and a handy ISO code cheat sheet, see our ISO Code Guide & Cheat Sheet It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.

It is important to note that each time a code increases, the quantity range of particles is doubling. Inversely, as a code decreases by one the contaminant level is cut in half.